Digital Factory Software Platform

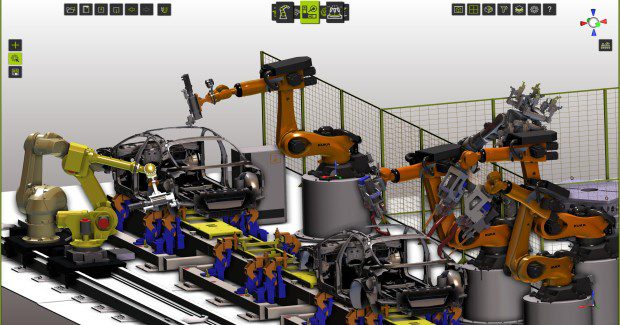

FASTSUITE Edition 2 from CENIT combines machine-based simulation, offline programming for robotics, virtual work cell layout, and component handling in one platform to provide a powerful alternative to existing software solutions for the digital factory.

Posted: March 29, 2016

The FASTSUITE Edition 2 software platform from CENIT North America, Inc. (Auburn Hills MI) combines machine-based simulation, offline programming for robotics, virtual work cell layout, and component handling in one platform to provide a powerful alternative to existing software solutions for the digital factory. FASTSUITE Edition 2 is designed to fill a market gap that exists between large PLM-based software providers and smaller proprietary simulation systems offered by robot manufacturers. This stand-alone simulation platform is focused on combining manufacturing concept validation, offline programming, and the virtual commissioning of production systems.

FASTSUITE Edition 2 is based on the concept of being non-proprietary with regards to vendor, process and technology, which means it allows for the integration and use of any robotic, machine, human or logistics component in a single simulation environment. Strong points of the software are ease-of-use, efficient programming functions for any robotic application, versatility and openness. Using standards for data exchange along with the automated optimization of such data, this platform can easily operate alongside with any existing CAD/CAM or PLM landscape.

https://youtu.be/SGbyPzsJ6Lo

Its modular architecture allows shops to interactively customize the software according to their needs in a couple of ways. An Automation System Integrator can make on-the-fly GUI or technological adjustments to the point of complete individualization, if necessary; the functionality can be catered to their needs. However, the software also delivers off-the-shelf packages for common manufacturing technologies and processes to give users the ability to get started right away. FASTSUITE Edition 2 imports data in three ways: CAD data via standard interfaces like IGES or STEP, and direct interfaces like NX, CATIA, SolidWorks etc. One of the more unique options is its ability to import and export work cell layouts and kinematic definition via the AML (Automation MarkUp Language) standard.

“For programming and simulation of robotic cells, machines, and production lines, companies in various industries have expressed a need for simplified and customizable software tools. This software architecture is based upon a common simulation platform that allows cross-process integration of any manufacturing technology. This provide a highly scalable, flexible and powerful solution,” explains Peter Koch, the director of digital factory solutions at CENIT. The main focus of the software is initially aimed at programming, simulating and the virtual commissioning of machine and robotic-based automation cells and lines. “To be able to do such tasks independently, the easy creation of new resources and cell layouts is also part of this solution offering for customers. Software modules for material flow and human behavior simulations, as well as additional aspects of process planning, will eventually be added,” said Helmut Ziewers, the vice president of digital factory solutions at CENIT.

CENIT North America, Inc., 691 North Squirrel Road, # 275, Auburn Hills, MI 48326, 248-309-3251, www.cenit.com/automate.