Hydroforming Reinvented

A new metal forming process has been introduced to economically produce metal parts that previously could not be formed.

Posted: March 7, 2016

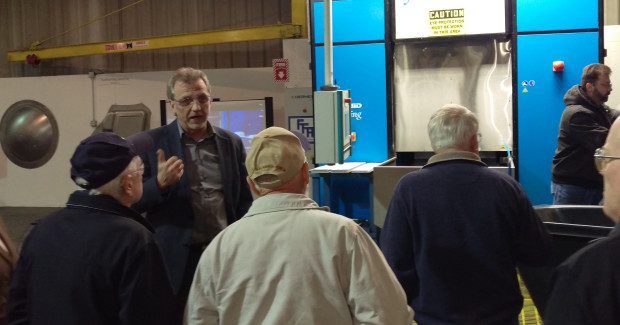

A metal forming process that utilizes H2O as the force to form parts at 60,000 psi was introduced to aerospace, automotive and medical parts suppliers and other local contract manufacturers during an open house event hosted by FluidForming Americas, LLC (FFA; Hartsville, TN) on Friday afternoon, March 4.

FluidForming Americas was founded and launched in August 2015 by Paul Benny, the company president; Dr. Jürgen Pannock, the chief technology officer; and Reinholdt Wesselman, the managing director of parent company FluidForming GmbH (Vechta, Germany) and the inventor of the fluid forming (FF) process. FluidForming Americas manufactures parts using fluid forming technology and leases FluidForming machinery in the Americas.

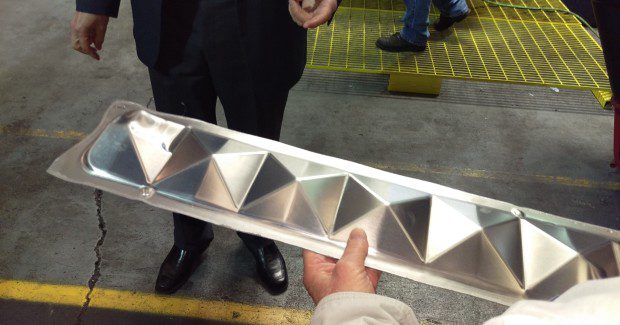

After lunch and opening ceremonies, Dr. Pannock walked through a presentation that explained fluid forming (FF) technology and the diverse application opportunities it opens for the design and formation of metal from .004 in to .1969 in (1.01 mm to 5 mm) thick. Water is forced at pressures up to 60,000 psi to economically create innovative metal part designs that could not be formed previously. The FF process is exceptionally cost effective for short run needs and prototyping of parts requiring less than 500,000 annually.

https://youtu.be/5FIMXGTYhbM

A tour of the facility followed and attendees got to see their Form Balancer 25 fluid forming machine in action to better understand the process technology and further discuss potential application opportunities. The FF process produces consistent, high quality parts with first pass yield results of 99.996 percent. This essentially eliminates rework and non-conformance of parts to reduce scrap and ensure consistent parts fit-up. Parts cross-contamination is removed as one side of the part comes into contact with only water. Lightweight metals can be used in lieu of castings, forgings, overly complex forms and plastics because the process virtually eliminates material overcompensation for thinning, internal stresses and springback, i.e., no more expensive and environmentally stressful castings.

The FF process has already been proven as ideal for making heat exchangers, bipolar plates, perforated metal sheets, system cases for personal computers, all sorts of kitchen accessories and laboratory equipment, and medical applicances.