Slash Overall Cycle Times

Using Production Module 7.1.1 from Third Wave Systems, shops can routinely generate cycle time reductions of 30 percent and have achieved up to 80 percent, all while simultaneously improving tool life.

Posted: March 30, 2016

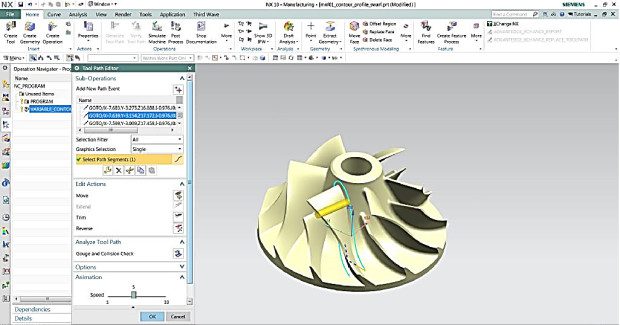

Third Wave Systems (Minneapolis, MN) has released Production Module 7.1.1 with several new features and enhancements, including a new Siemens NX interface. The new XChange NX interface for Production Module allows shops to easily import, optimize and upload their part programs using process data contained within Siemens NX to streamline project setups and store optimization data, all while adhering to the established PLM process within Siemens NX. While achieving all of these benefits, Production Module also improves cycle time by more than 20 percent for turning and more than 25 percent for milling, as well as performing cutting-edge analysis that improves tool life and part quality.

The v7.1.1 release also has an enhanced Mastercam interface that allows users of Mastercam X9 to reap the benefits of bi-directional integration and achieve cycle time improvements faster. An improved navigation tool bar is also included in Production Module, in addition to the earlier improvements for split arc optimization, plunge milling operations, simulation times averaging 30 percent faster, and improved accuracy for small chip loads when simulating turning processes in Production Module 2D. Production Module offers a beta advanced toolpath interpretation functionality and batch queueing functionality; 2D and 3D algorithm improvements for improved modeling for indexable mills and enhanced force and optimization improvements; updates to the Japanese interface; upgraded data validation with messaging functionality; an XML file structure that dramatically reduces simulation setup time; and license management functionality with monitoring capability.

Production Module users routinely generate cycle time reductions of 30 percent and have achieved up to 80 percent, all while simultaneously improving tool life. Engineers who use Production Module are able to work offline to gain better tool life information than other simulation packages or trial-and-error testing. To obtain this information, Production Module uses a library of more than 120 experimentally validated material models to reduce machining time, improve product quality and get products to market faster. Third Wave Systems software is used by the aerospace, automotive, medical, heavy equipment, cutting tool and oil and gas industries.

Third Wave Systems, 6475 City West Parkway, Minneapolis, MN 55344, 952-832-5515, Fax: 952-844-0202, sales@thirdwavesys.com, www.thirdwavesys.com.