Cutting Wheel for Heavy Duty Steel and Stainless Steel Jobs

The ZIP+ XTRA cutting wheel from Walter Surface Technologies uses an exclusive, patented rib design that reduces friction on the surface for faster and cooler cutting in the most demanding applications.

Posted: April 6, 2016

Walter Surface Technologies Inc. (Windsor, CT) offers the ZIP+ XTRA cutting wheel that is specifically designed to easily cut through steel or stainless steel in heavy duty applications. This cutting wheel features an exclusive, patented rib design that reduces friction on the surface for faster and cooler cutting. It is 1/16 in thick to last longer while cutting through heavy duty applications with safety and precision. It is ideal for metal fabricators, manufacturers and contractors who are looking for a fast, smooth and efficient cut for their most demanding applications. The ZIP+ XTRA comes in exclusive protective packaging that preserves the wheel’s physical properties until ready for use so that performance and safety are kept at the highest standards possible.

Through extensive laboratory test, ZIP+ XTRA was found to provide the most amounts of cuts than other comparable cutting wheels on the market because it is designed with a new formulation of zirconium grains that are more durable against the toughest materials. “This cutting wheel is called ZIP+ XTRA because we wanted to emphasize that it is extra safe, extra strong and extra tough,” noted Marc Brunet-Gagne, the product manager at Walter Surface Technologies. “With this new formulation, we are able to produce a product that can cut through the most demanding cutting applications with ease and therefore reduce costs associated with wheel changeover, as well as costs related to the amount of wheels used throughout the year. In addition, this cutting wheel produces less dust when compared to other competitive wheels, making it a safer solution for workers and the work environment.” The ZIP+ XTRA is available now in 4 ½ in and 5 in diameters.

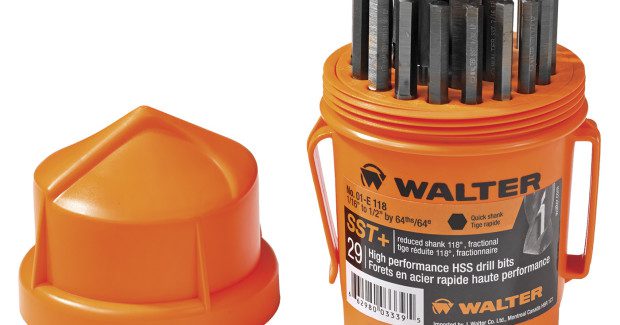

In other equipment applications, Walter Surface Technologies offers their bright orange-colored Drill Bit Carrying Case that is made of shock resistant, extra-thick polyethylene plastic materials that help protect drill bits products from water, rust, oil, grease and other contaminants. All-purpose Walter drill bits offer heavy-duty, fully ground body construction, special bronze SST heat and surface treatment, a state-of-the-art self-centering split point and high flow spiral design for the fastest removal rate. Available for high-performance HSIS Walter drill bits, such as the SST 118® Quick Shank and the SST+ 135® Quick Shank, the Drill Bit Carrying Case offers a closed, quick-release belt clip that gives users a practical way to realistically work with a 29-piece drill bit set.

“Our high-performance HSIS drill bits feature strong cobalt-blend bodies to reduce the changes for melting and deformation, self-centering, and no pre-drilling needed. These powerful and innovative drill bits must be protected, and this carrying case provides shops with a conveniently mobile method to protect their valuable drill bit investment,” said Stephane Drainville, the product manager at Walter Surface Technologies.

Walter Surface Technologies Inc., 810 Day Hill Road, Windsor, CT 06095, 860-298-1100, Fax: 866-274-4435, info.us@walter.com, www.walter.com.