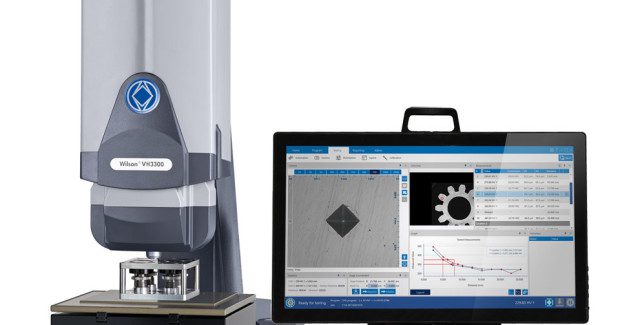

Fully Automated Hardness Tester

The Wilson VH3300 Vickers / Knoop fully-automated hardness test system from Buehler is ideal for more advanced heat treatment processes like the aerospace, energy, construction and transportation industries that require hardness testing systems to be durable while maintaining precise control during critical test data generation.

Posted: April 8, 2016

Buehler (Lake Bluff, IL) has introduced the new Wilson VH3300 Vickers / Knoop fully-automated hardness test system for superior accuracy, repeatability, improved safety and an overall enhanced user experience. The Wilson VH3300 model, with its extensive variety of scales and magnifications, excels through maximum flexibility for automated hardness testing to ASTM and ISO in the test laboratory, in materials and product development, in clean production environments and in routine quality control. It is ideal for more advanced heat treatment processes like the aerospace, energy, construction and transportation industries that require hardness testing systems to be durable while maintaining precise control during critical test data generation.

The VH3300 is equipped with the patent-pending collision protection technology, a high-speed sample stage and the DiaMet™ universal testing software. This hardness test system features a 6-position test head with up to three indenters and three zoom objectives, an automated X/Y sample stage available in two sizes (180 mm x 180 mm as standard) and a powerful image analysis system. A wide range of test loads from 5 g to 60 kg (depending on configuration) renders the sturdy system suitable for a wide variety of applications. A purpose-designed collision protection system helps to avoid accidental damage to the indenters and objectives due to operator errors.

The VH3300 hardness testing system provides the ultimate high capacity testing platform capable of performing 150 make and measure indents an hour using the fully automated test program. A high-resolution digital camera and long working distance objectives, in combination with innovative, calibrated digital zooming capability, provide up to 2000X magnification. The entire system is controlled through the DiaMet hardness automation software, including setting of test parameters, automated indentation and measuring, acquisition of test data, statistical analysis, data export, and a range of other functions speeding up the test procedure and ensuring high-accuracy acquisition and analysis of test data.

“We have created this new system into a top-notch product in terms of precision, repetition accuracy and user friendliness,” explains Marcel van Banning, the Wilson Hardness product manager. “This fully automatic Vickers/Knoop hardness test system is capable of meeting virtually any requirement in the area of automated micro hardness testing. This is an example of how we are committed to innovation based on customer feedback.”

Buehler is part of the Test and Measurement Group of the U.S.-based Illinois Tool Works (ITW) group of companies, with more than 850 distributed business units in 52 countries worldwide and a staff of approximately 60,000. As a leading provider of scientific equipment, supplies and analysis techniques for use in materials preparation, image analyses and hardness testing, their products are used throughout the world in manufacturing facilities and quality laboratories in the primary metals, automotive, aerospace and defense, electronics, medical and energy industries.

Buehler, 41 Waukegan Road, Lake Bluff, IL 60044, 847-295-6500, info@buehler.com, www.buehler.com.