Magnets for Holding, Lifting, Fixturing, Fabrication, Welding and More

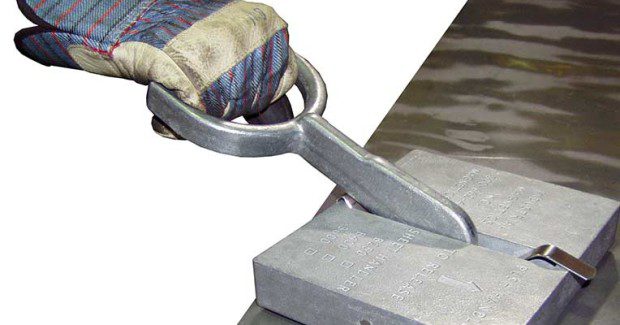

Industrial Magnetics offers lifting magnets, manhole cover lifts, welding magnets, magnetic sheet fanners and Transporters that increase the speed, efficiency and safety of material handling operations involving metal.

Posted: April 9, 2016

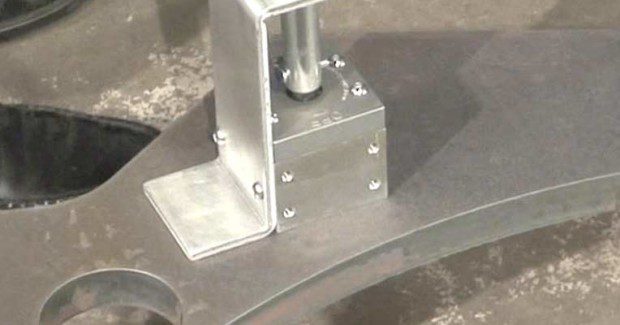

Industrial Magnetics, Inc. (IMI; Boyne City, MI) has a 40-page full color catalog titled “Magnets for Holding, Lifting, Fixturing, Fabrication, Welding and More” that includes over 70 part numbers for increasing the speed, efficiency and safety of material handling operations involving metal. Product offerings include magnetic holders for welding torches, air tools, cups and spray guns, adhesive backed cup magnets and Max-Attach™ Polymagnets® for high-performance holding. Updates on the full IMI line of lifting magnets, manhole cover lifts, welding magnets, magnetic sheet fanners and Transporters® are also included. The catalog is available to download by clicking here (registration required), or a hard copy can be requested by calling 888-582-0822.

IMI also offers a free, no obligation plant audit to companies interested in evaluating the performance of their existing magnetic separation equipment. As magnets can potentially lose strength over time due to factors such as wear, damage, and exposure to heat or electrical surges, it is important to routinely examine the magnetic equipment to ensure that it is operating within an acceptable threshold. For companies that choose to participate in a Free Plant Audit, a qualified IMI technician will conduct an onsite evaluation to perform objective and measured strength testing of existing magnetic equipment, test end product for metal contaminant levels, identify key areas where magnets should be installed to enhance operating performance and offer a comparative and cost analysis for new or upgraded magnetic equipment.

Upon completion of the audit, full documentation will be presented to the customer, along with recommendations for correctable action that may need to be taken in order to return the magnet to its optimal performance level. Additionally, if there is a minimum qualifying purchase resulting from the Free Plant Audit, IMI will provide a Pull Test Kit (a $400 value) at no charge, allowing the customer the ability to self-monitor their magnetic equipment on a regular basis. IMI also offers free product testing at their onsite research and development facility that features hundreds of magnets, weigh scales and PPM analyzers for use in determining the proper magnetic solution for an application. They are currently featuring a “Trade-In/Upgrade” promotion on certain magnetic separators, which allows a customer to trade-in their old magnetic equipment for a discount off of a new, stronger model.

In other equipment applications, IMI offers their Polymagnet® Demo Kit for product designers and engineers that allows users to explore and experiment with the various magnetic functions now made possible with this next-gen magnetic circuitry. Polymagnets are unique in that the surface of the magnet is encoded with a pattern of multiple north and south poles. The polarity pattern can be specifically designed to achieve a desired result or function. These magnetic functions, such as super-strong attachment, shallow field, magnetic spring, magnetic latch, and repelling up close or at a distance, are not possible with conventional magnets, which only possess a singular north and south pole.

“Sometimes the best way to really understand the capabilities of new technology is to show people rather than tell them about it,” states Paul Hardy, a Polymagnet product specialist at IMI. “We created the DemoKit so that product designers could hold these in their hands and more easily visualize, brainstorm and test their ideas for Polymagnet applications.” The Demo Kit comes in two sizes and contains various Polymagnet samples that showcase these functions. Also included is a new high-res magnetic viewing film for visualizing the magnetic pole patterns in vivid yellow/green color.

Industrial Magnetics, Inc., 385 M-75, Boyne City, MI 49712, 231-582-3100, www.magnetics.com.