Simple Marking of Medical Devices

The simple, safe and robust TruMark Station 3000 workstation from TRUMPF is ideal for shops with small or medium batch sizes that want to integrate the marking process into their production lines.

Posted: April 2, 2016

TRUMPF Inc. (Farmington, CT) showcases the diode-pumped vanadate TruMark 1110 laser – part of their innovative and cost-effective series of entry-level marking lasers – in their new TruMark Station 3000, a compact marking station that offers users a high degree of flexibility in marking. With an automatic door and intuitive operation, the TruMark Station 3000 is ideal for shops with small or medium batch sizes that are looking to integrate the marking process into their production lines with a simple, safe and industrially robust workstation. Its motorized Z-axis aids in achieving the precise focus position during component positioning. An optional Focus finder takes this one step further. Integrated lighting and a variety of windows provide a clear and safe view of the workpiece.

The compact cube design of this marking station offers a true desktop solution with no additional supply unit required when combined with the TruMark 1110 or TruMark 5010 marking lasers, yet it can be combined with any marking laser in the TruMark Series 1000, 3000 or 5000. To integrate it into an automatic assembly line, simply remove the transfer flaps on the side of the workstation. This flexibility enables users to utilize the TruMark Station 3000 from start-up to series production.

The TruMark Station 3000 features the impressively compact TruMark 1110 laser. The beam source, controls, internal focal position control, and scanner are found with an enclosure that is roughly the size of a shoebox, which simplifies installation or integration into production lines. When marking, the laser offers very good beam quality, high peak pulse power and superb repetition frequencies to process medium-sized batches with great reliability. Internal control of the focal position and impressive pulse-to-pulse stability result in consistent and fully repeatable marks at pulse widths of less than 25 ns. Since the TruMark 1110 operates in the infrared range, it is ideal for marking metals, plastics and even leather. Regardless of the industry or application, the TruMark 1110 guarantees parts meet any traceability requirements.

All TRUMPF equipment is designed for an industrial and highly demanding manufacturing environment. With the proven TruTops Mark software, operators easily connect with user-specific databases or control systems, existing databases and ERP systems to eliminate manual data entry and the associated risk of error. Integrating auxiliary devices, such as a barcode reader, is also simple. In addition, the TruMark Observer, an integrated camera system, is able to read data matrix codes and easily identifies the position and alignment of a workpiece.

In other equipment applications, TRUMPF also offers their second generation TruLaser Cell 8030, a multi-axis machine designed specifically for laser cutting hot stamped 3D components that is more productive and energy-efficient than its predecessor, has lower investment costs and features a modular design for flexible configurations. The machine’s increased productivity is primarily due to its highly dynamic rotational changer and new rotary indexing table, which features up to three workstations. The areas for loading and unloading are completely separate from each other, facilitating semi-automated solutions and increased productivity. Loading/unloading can be done with two people, or a single person can load the machine while a robot unloads the system. Either solution can be achieved while the system is actively processing a part inside of the machine.

Not all cuts require the same laser power, so fabricators can select the best laser for the TruLaser Cell 8030 based on their application. The new TruDisk 2000, a 2 kW solid-state laser, offers high energy efficiency and excellent beam quality for fast, cost-efficient processing. It is the ideal laser for highly complex part processing. For applications requiring higher laser power, for example, when producing long cuts in larger parts, the machine can be equipped with up to 4 kW of laser power. The process reliability and stability of the TruLaser Cell 8030 has also been improved, with new functions such as ObserveLine for visual slug detection. Using extremely fast and dependable sensors in conjunction with the laser beam, detection occurs twice as fast as any other system currently available on the market.

A residual runtime display, built into the front of the machine, is another new feature that visually indicates how much processing time remains for the current component and provides additional information about the status of production to keep operators aware of the production cycle and managers current on the production status. The TruLaser Cell 8030 also features a compact footprint. Since the electrical control units are built into the body of the machine, the system can be quickly and easily integrated into existing production environments. Installation costs for the new TruLaser Cell 8030 have been reduced: whereas the old system required three supply cables to the machine, the optional centralized power supply now requires only one.

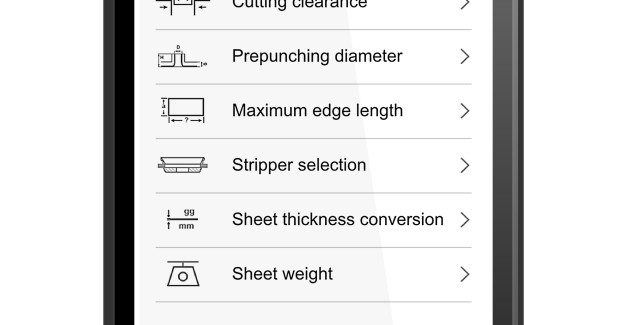

TRUMPF also created the PunchGuide app that simplifies many calculations and supports users of punching and combination punch laser machines. This practical app makes it easier than ever before to determine the calculations involved with punching. Packed with comprehensive expertise in mechanical engineering and punching technology, the app is designed for use with smartphones or tablet PCs. The PunchGuide app puts the most important parameters at the fingertips of production supervisors, engineers and operators and offers support for a variety of calculations, including punching force, cutting clearance, pre-punching diameters, maximum edge length, stripper selection, and calculations for sheet metal thickness conversion and sheet weight. The user can easily specify whether the results are given in metric or inch units of measure, and can also store data for their own machines for future use.

This mobile app can be installed at no charge in German, English, French, Italian, Spanish, Czech and Chinese versions for the iOS and Android operating systems, as well as in a Web version. For more information, visit www.trumpf.com/apps/punchguide.

TRUMPF Inc., Farmington Industrial Park, 111 Hyde Road, Farmington, CT 06032, 860-255-6104, www.us.trumpf.com.