3D Printing Drones on Demand

With 3D printers available commercially and becoming less expensive every year, the development of additive manufactured drones for both commercial and military capabilities is growing in importance. Welcome to the Age of the Jetsons.

Posted: May 3, 2016

In the future, it may be possible for military jet pilots to manufacture and deploy small 3D printed drones to conduct surveillance or help perform search-and-rescue missions. That capability to produce unmanned aerial systems on demand could be onboard aircraft in 2040 or even earlier, according to scientists and engineers at BAE Systems, Inc. (Arlington, VA). Additive manufacturing, the technical term for 3D printing, is the process of creating an object by layering substances, gradually forming the part. Traditional manufacturing processes, on the other hand, take a piece of raw material and then cut or grind it down to form the needed component. Although the technology has been around since the 1980s, it has predominantly been employed for modeling and prototyping. As printer resolution and material strength improves, the technology is now leaping forward at a rapid pace.

BAE scientists envision a future when a pilot can request unmanned aircraft system (UAS) support mid-mission. Then, engineers sitting in a remote location could send computer-aided design data – basically a blueprint for a 3D printed component – to an onboard printer, which would print a drone with the size, range and payload capability to support whatever operations are ongoing. “This creates the ultimate adaptable taskforce, with a lead aircraft able to enter any unknown scenario and quickly manufacture an effective toolset for any task,” a BAE news release stated. A machine that can construct a drone from scratch in a matter of minutes sounds more like a gag from “The Jetsons” than a credible future technology, but industry is already hard at work figuring out just how to make that happen.

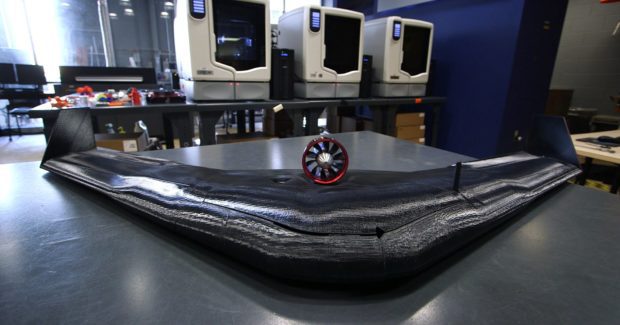

A team of researchers from the University of Virginia have already built the Razor: a small, 1.8 lb UAS with an airframe constructed of nine 3D-printed parts that join together to form a flying wing. “It comes out of the printer, you snap it off the tray, and you click it into place. It’s that easy. There’s no post-processing at all,” said David Sheffler, a lecturer at the university and a former Pratt & Whitney engineer who leads the project. The airframe is manufactured in about 31 hours using a technique called fused deposition modeling (FDM), in which a material is melted and dispensed layer-by-layer to form a structure. The Razor’s electronics – such as the motor, servos, autopilot and batteries – are all off-the-shelf components, and its computational powerhouse is an Android smartphone.

Solid Concepts Inc. (Valencia, CA), an additive manufacturing provider, already uses the technology to produce fixed-wing UAS airframes, said Frederick Claus, their business development manager. The company can create the fuselage, wings, nose cone and tail for multiple aircraft overnight. Both Sheffler and Claus believe that it will become possible to print an entire drone, including its electronic components, batteries and motor, in a couple of decades. “Making 3D printed electronic circuitry is almost a no-brainer,” Sheffler commented. “Making motors with windings and that type of geometry, I think there’s some work to do with that, getting wiring to the point where you can print that out, but I absolutely think that’s feasible in the next 20 years or so.”

Claus believes the military could have a limited capability to print UAS as early as 12 years from now. Those aircraft would not be durable, high-performance systems, but he thinks they would get the job done. “If a special forces guy needs to print a UAV, and all he has to do is fly it over the hill and find the bad guys . . . they might just fly it, and then when they’re done with it, they push a button and blow it up,” said Claus. But if such a technological leap is to occur, he also noted that additive manufacturing companies and the government must get to work developing industry standards for 3D printers and materials. Printers, materials and processes must all be qualified.

For instance, Claus noted that few companies have developed “design allowables” that measure the strength of a material based on engineering and performance data. Such information is necessary to give manufacturers and customers confidence in the structural integrity of a component. “Once you have that kind of information, which is really powerful, you can now take it to the Navy, you can take it to the Federal Aviation Administration, you can take it to anyone that’s interested and convince them that it’s real, it’s legitimate and that they should use it,” he added.

According to Sheffler, additional short-term challenges include figuring out how to speed up the printing process and developing new, stronger materials. The FDM process used to make the Razor, for example, took a laborious 30 seconds per layer. He noted that other machines that use different printing techniques can layer materials in seconds and at greater resolution, but those systems are limited to specific materials. Because an airframe must be constructed out of a strong, lightweight material, that limits the options available. Claus believes these kinds of barriers can be eliminated in about a decade. “Ten years out, those things aren’t going to be issues anymore,” he said. “These things we’re talking about in concept are going to be real.”

But as the technology proliferates, Sheffler said there will be other challenges. For example, 3D printed drones are most often thought about in an offensive context, of soldiers deployed in a warzone printing a drone that can fly beyond the line of sight and conduct surveillance on enemy forces. However, Sheffler pointed out that it’s just as important from a defensive standpoint to develop additive manufactured drones. With 3D printers available commercially and becoming less expensive every year, it might not be long before U.S. adversaries design and manufacture their own systems.

“Anything I’m doing, the bad guys can do. They’re probably thinking about it and they’re developing that capability,” added Sheffler. “I think what we’re doing is trying to understand what those capabilities are so that we can be ready for them. What do you do to combat that? How is this going to be a threat, and then what do you do to counter that threat? I think that’s really probably the more important side of what we’re doing here – understanding what you have to do to protect yourself, because it’s coming.”