The Additive Manufacturing Factory of Tomorrow

This modular integration of machine technology and plant architecture is an Internet 4.0 promise of new levels of quality, flexibility and increased performance in additive manufacturing, as well as a radical new approach to the design of process components that could ultimately create faster and more economic industrial production solutions.

Posted: May 3, 2016

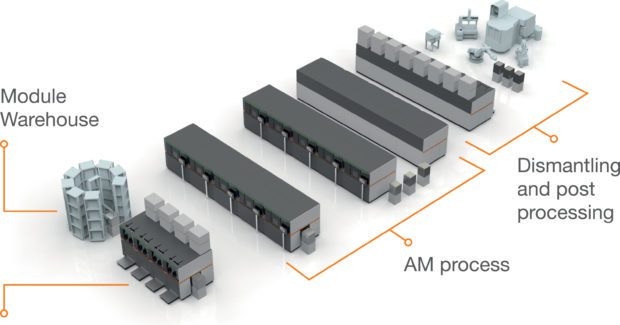

A new machine and plant architecture from Concept Laser GmbH (Lichtenfels, Germany) shows that the vision of Industry 4.0 has already become firmly integrated in the company’s strategy. The “AM Factory of Tomorrow” is the modular integration of machine technology that promises a new level of quality, flexibility and increased performance in additive manufacturing (AM), as well as a radical new approach to the design of process components that could ultimately create faster and more economic industrial production solutions.

Machine and plant technology have historically relied on “more laser sources,” “more laser power,” “faster build rates,” or “expansion of the build envelope sizes” that treated machine technology as an island without any consistent integration into the manufacturing environment, where building job preparation and building job processes proceeded sequentially. Now, the new machine architecture of the AM Factory of Tomorrow attempts to expand the usually quantitative sections of manufacturing with new, qualitative aspects.

“In essence, this is about splitting up build job preparation/build job follow-up processing and additive manufacturing into any number of combinable modules,” explains says Dr. Florian Bechmann, the head of research and development at Concept Laser. “With comparatively large build envelopes, build jobs can be carried out with a time delay. The intention is to drastically reduce the downtimes of previous stand-alone machines. There is plenty of potential here for improving the level of added value in the production chain. In contrast to purely quantitative approaches of previous machine concepts, this is a fundamentally new approach for advancing industrial series production one step further.”

THE PLANT ARCHITECTURE

At present, regional 3D printing centers are being created as service providers all around the globe. This development is characterized by the transition from prototyping to a desire for flexible series production at an industrial level. In these centers, the AM users experience the pressure of traditional manufacturing: demand for space, expansion of the machinery, increasing operating tasks and, in particular, cycle times. But in the AM Factory of Tomorrow, production is “decoupled in machine terms” from the preparation processes. The time window for AM production is increased to a “24/7 level,” meaning there is higher availability of all components. An automated flow of materials clearly reduces the workload for the operators. Interfaces integrate the laser melting machine into traditional CNC machine technology (which is important for hybrid parts, for example), and also into downstream processes (post-processing/finishing).

The new plant architecture essentially decouples pre-production, production and post-processing. This includes, among other things, flexible machine loading and physical separation of the setting-up and disarming processes. The objective is to coordinate the process components in a more targeted way with interfaces and increase the flexibility of the process design to create an integrated approach. This becomes possible through a consistent modular structure of “handling stations” and “build and process units” that, in terms of combination and interlinking, promise considerably greater flexibility and availabilities. It will also be possible to handle diverse materials better and more economically through a targeted combination of these modules.

For example, the future machine user will use the modules to very precisely customize the production assignment to match the part geometry or material. The overall level of efficiency and availability of the production system will increase markedly, along with a significant reduction in the amount of space required. Simulated production scenarios show that this space can be reduced by up to 85 percent compared to current possibilities that are available. Also, the laser power per sq m is increased seven-fold. “The build rates increase enormously thanks to the multilaser technology,” notes Dr. Bechmann. “The build envelope sizes also experience considerable growth. We now want to use an integrated machine concept to highlight the possible ways that the approaches of Industry 4.0 can change additive manufacturing as the manufacturing strategy of the future. There is great potential to increase industrial added value and enhance suitability for series production.”

THE MODULAR PROCESS STATION

The process station shown has a build envelope of 400 x 400 x >400 cu mm. Its laser sources, process gas management and filter technology are integrated in the module and the layer thicknesses are within the usual range. This machine solution also has a variable focus diameter and will be available optionally with 1, 2 or 4 laser optics with a laser power ranging from 400 W to1,000 W. An available redundancy of the lasers will ensure that, if one laser fails, the remaining three lasers will still cover the entire build plate so that the build job can still be completed. “More and more laser sources only increase the expected speeds to a limited extent,” states Dr. Bechmann. “But ultimately they also increase the level of complexity and dependencies that can result in vulnerability – and turn the desired positive effect into a negative.”

THE MODULAR HANDLING STATION

The new handling station has an integrated sieving station and powder management. There is no longer any need for containers to be used for transportation between the machine and sieving station. Unpacking, preparations for the next build job and sieving take place in a self-contained system without the operator coming into contact with the powder. But what makes the modular handling station so attractive is its specific configurations: a handling station can be linked to two process stations to create a manufacturing cell. The factory building kit also enables several handling stations to be joined together to create a material preparation facility and be physically separated from the process stations.

COMBINATIONS OF MODULES

The new factory building kit boasts three types of modules: process module, dose module and overflow module, which are to be offered in different heights. The direct link between these modules – without the use of any pipes or tubes and their identification via RFID interfaces – is remarkable. This results in a reliable flow of materials with high material throughputs, along with great flexibility when there is a need to supply different types of materials for the build process and handle them. “In the future, we think that AM factories will be largely automated,” says Dr. Bechmann. “Envision the transport of material or entire modules being handled by driverless transport systems. This could become the next step in the development. Additive manufacturing can be automated to the maximum extent.”

A NEW TYPE OF 2-AXIS COATING PROCESS

The new machine concept includes a new type of 2-axis coating system that enables the return of the coater to be performed in parallel with exposure for a considerable time saving during the coating process. The coater blades, optionally made of rubber, steel or carbon, can be changed automatically during the build job. “An automated tool changing system, as is the case with CNC machine technology, promises a high level of flexibility, time advantages when setting up the machine, and reduces the level of manual intervention by the operator,” explains Dr. Bechmann. “We deliberately talk here about ‘robust production’.”

Concept Laser Inc., 1000 Texan Trail, Suite 150, Grapevine, TX 76051, 817-328-6500, info@conceptlaserinc.com, www.conceptlaserinc.com.