Automated Welding Redefined

The new TPS/i Robotics welding power source from Fronius is specially tailored to the demands of robot-aided welding, with integrated and fully synchronized system components that enable robots to weld faster with a higher degree of repeatability.

Posted: May 10, 2016

Fronius USA LLC (Portage, IN) offers their new TPS/i Robotics welding power source that is specially tailored to the demands of robot-aided welding. Thanks to integrated and fully synchronized system components, it enables robots to weld faster with a higher degree of repeatability. Shops can achieve and maintain unprecedented levels of quality with its advanced yet easy-to-use functions. Engineers have drawn on the power source’s consistently implemented digital system architecture and new communication technology features to cover and address all the major influencing factors crucial to the welding process with high definition and reaction speed. The result is an exceptionally stable arc and optimum welding results.

A crucial role is played by the modified dip transfer arc (LSC – Low Spatter Control) and the modified pulsed arc (PMC – Pulse Multi Control) that give the welder a significantly higher level of control over the arc. The user is also supported by brand new stabilizers: while the penetration stabilizer ensures that the penetration remains constant – even if stick out fluctuations occur – by adjusting the highly dynamic wirefeeder, the arc length stabilizer keeps the arc at an optimum length when the arc geometry (e.g. due to a change in the weld seam profile) or weld pool temperature changes. This means TPS/i Robotics not only makes the welding process considerably quicker than ever before, but also enhances the weld seam quality. One of the visible improvements is the minimal amount of spatter produced.

New paths are being forged in the area of communication between the welding system and robot control. Like all other process control components, the TPS/i system’s new robot interfaces are incorporated into the system bus architecture and are therefore able to provide data relevant to the robot control in real time. A new Interface Designer allows the robot interface to be programmed quickly and conveniently offline using a graphical user interface. Shops can configure and adapt the interface to their own individual requirements at any time. Pre-prepared interfaces are provided to the control systems of leading robot manufacturers. Another benefit of the power source’s consistent digitalization is the continuous collection of information on the current status of the power source and on every weld seam, which is made available to the user. Documentation and analysis of process data is increasingly significant in welding technology. This detailed data can be used to monitor, analyze and document the welding process. Using the WeldCube central server unit, the data gathered from several power sources via their Ethernet interfaces can be combined and managed from a company-wide perspective.

The WeldCube server is based on an industry PC (IPC) with integrated software that is used to connect up to 50 power sources via the network. The system is compatible with all digital Fronius series units, with resistance spot welding system DeltaSpot, and with intelligent welding device platform TPS/i. This enables the shop to document and evaluate a wealth of data, including current, voltage, wire speed, welding speed and time, arc and dynamic correction, and job numbers during manual and robot-aided welding processes. This data is visualized in order to achieve an accurate analysis, then output via a web browser, which enables the results to be accessed conveniently from any computer or mobile device.

Thanks to Plug & Play, installing the WeldCube is extremely easy. Once the system is up and running, virtually zero maintenance is required to keep it running. This technology also providing updates that the shop can install themselves. Individual adjustments and programming are not a problem because the standard functions can be upgraded by means of different packages offering a variety of new features. As a result, customized solutions tailored to meet the shop’s exact requirements can be implemented.

The extensive functions of the WeldCube ensure a wide range of different uses are possible: The actual values for each power source can be documented both in relation to the machine and overall in real-time. The user can continually monitor and evaluate additional and consumption data relating to gas, wire and energy consumption, for example. Set values, such as job data, can also be observed and recorded by the system for the entire service life of a welding system. When used in combination with the TPS/i welding device platform, it is possible to edit jobs and make comparisons across power sources. All the values can be exported in different file formats or printed out from the IPC directly.

A range of analysis tools are available for fast and reliable troubleshooting, enabling shops to monitor the quality and output of their welding processes and, if necessary, optimize them. Continuous data analysis can also prevent production downtime and increases safety. Different service packages ensure that the shop gets a system that has been installed 100 percent correctly, is perfect for them, has a high level of availability – and one they can operate without any difficulty.

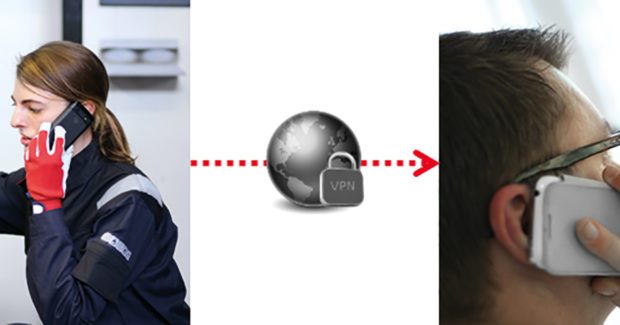

Also, with the latest TPS/i power source platform, users have FeeL (Fronius everytime easy Link) to conveniently access welding current sources from their workplace PC, smartphone or tablet using a LAN connection. FeeL makes it possible to access the hardware and software configurations online, analyze data and, if required, carry out updates or fix operating faults. If required, the Fronius Support team can grant direct access to the power source using a secure internet connection (VPN) initiated by the user as part of the enhanced Feel Remote Support service package. Power source owners can then receive error diagnosis or process optimization support wherever they are and update their software.

Many engineer call-outs to the power source that were previously been necessary can now be avoided completely through the FeeL remote service. On-site analyses in preparation for a repair appointment is also unnecessary with the TPS/I; the service engineer can come fully prepared with the correct spare part following an online diagnosis. If welding systems are exposed or difficult to access, this helps to save money spent on expensive engineer hourly rates, avoid downtime and guarantee that the power sources are fully operational.

Included in the FeeL service package is Xplorer Basic, which enables connections to the power sources to be established quickly. It can be used by internal employees to remotely access the power sources at any time over the company network with an existing LAN connection. They can access information about installed hardware and software and back up the system, as well as restore it if necessary. As an alternative to Xplorer Basic, any commercially available browser can also be used, but the connected power sources will not automatically recognize it so it will be necessary to enter the IP address manually.

If the welder or the company’s own maintenance requires additional support when operating the power source or fixing problems, they can contact Fronius by telephone and request support as part of the FeeL Remote Support service package. As soon as the operator of the power source has agreed to the terms of use and to establishing a secure connection with the company expert, the power source produces a unique security code (similar to a mobile TAN for internet banking). The expert is granted access to the power source only once this code has been entered and can then view the basic data and give instructions for optimizing processes and fixing faults over the telephone.

In the same way, additional functions in the form of characteristics or new processes can also be enabled if required and updates can be carried out. The operator on-site therefore retains full control over the power source and can terminate the connection at any time. The data is transmitted in encrypted form throughout the session and is also protected against tampering. To ensure that there is a record of the actions taken that can be referred to at a later date, the support staff’s activities are logged with a time stamp and the recording log is kept.

FeeL and FeeL Remote Support are ushering in a new era of support for welders and operators of power sources. Using this remote service means that power sources can be used more productively, the number of engineer visits can be drastically reduced, and servicing can be prepared for and carried out more effectively on-site. This remote service also opens up the possibility of adapting the functional range of the TPS/i welding systems to the latest welding task subsequently, therefore breaking new ground in the usage and cost structuring of welding current sources.

Fronius USA LLC, 6797 Fronius Drive, Portage, IN 46368, 219-734-5701, gibson.stephanie@fronius.com, www.fronius.com.