Automating the Factory Environment

Imagine whole-plant environmental automation data feeding smart control systems in your shop that respond in real time and learn over time to anticipate and respond to the needs of the humans in your shop – perhaps even better than the humans can. It’s time to start thinking about your environmental systems in a whole new way – or maybe stop thinking about them at all. After all, they’ll soon be able to take care of themselves.

Posted: May 6, 2016

You’ve probably already put a lot of thought into automation for your production processes. But what about environmental factors like air quality, lighting and temperature? New technologies will soon make it easier than ever to maintain a safe, healthy and productive environment, while reducing maintenance and energy costs.

ENVIRONMENT MATTERS

Human beings can adapt to a wide range of environmental conditions. But shops hoping to optimize productivity, improve retention and recruiting rates, and minimize complaints and absenteeism pay close attention to the working environment for their employees. Factors like air quality, temperature, light levels, noise levels and humidity can make a big difference in employee satisfaction, productivity and even accident rates. Many plants are using centralized, programmable HVAC and lighting controls that allow them to monitor and control systems for an entire facility – or all of their facilities – from a single location. These systems are a step in the right direction. But tomorrow’s environmental systems will be more than programmable. They’ll be smart, automated and connected, so they can make their own adjustments based on real-time data and anticipate needs that haven’t been programmed in.

Imagine these scenarios:

- Your dust collector monitors particulate level patterns over time and adjusts its equipment settings and maintenance schedule based on the data.

- Your HVAC system notices that the post-lunch productivity slump can be combatted with a brief blast of cooler air, and programs itself accordingly.

- Your lighting system automatically adjusts itself to optimize light levels for certain tasks in response to patterns of employee activity or equipment use.

It will all soon be possible, thanks to the Internet of Things.

BRINGING THE INTERNET OF THINGS TO THE FACTORY FLOOR

The Internet of Things (IoT) is already revolutionizing the home by connecting appliances ranging from thermostats to washing machines to users, manufacturers, utility companies and each other. These smart appliances are able to automatically adjust their behavior to external conditions, alert their owners if they need attention and sometimes even connect to repair technicians for troubleshooting. These same technologies are now making their way to the manufacturing floor. Lights, HVAC equipment and air quality equipment can be connected to each other and to operators via the internet. Smart automation requires several elements:

- Connection: Smart machines must have ways to connect to operators, sensors, control systems and each other – usually via WiFi or Bluetooth. Two-way communication allows operators to control equipment from anywhere and allows machines to send status updates and alerts to operators.

- Awareness: Sensors allow smart machines to monitor different aspects of their environments such as temperature, motion, particulate levels or the presence of certain chemicals. Wireless sensors can provide information from across the factory floor – or across the world.

- Responsiveness: Smart machines are able to respond to that sensor data in a variety of ways. At the simplest, they may turn on or off or sound an alarm. More complex control systems may allow machines to perform simple troubleshooting actions or send detailed notes to a repair technician.

But the critical factor that truly separates smart machines from existing technology is learning. Any thermostat can shut off the furnace when the temperature reaches a set level – but only a smart thermostat can learn from its operators’ behavior over time and automatically adjust itself to increase comfort, decrease energy use or both. Companies like Nest and Amazon have introduced smart, learning appliances to consumers. These learning machines are driven by sophisticated algorithms that can analyze data coming in from sensors and operator inputs, make predictions about future needs, and proactively adjust the equipment settings to meet specific goals. Smart environmental controls will make it easier to control energy use, meet regulatory requirements and keep employees happy and productive.

AUTOMATING AIR QUALITY

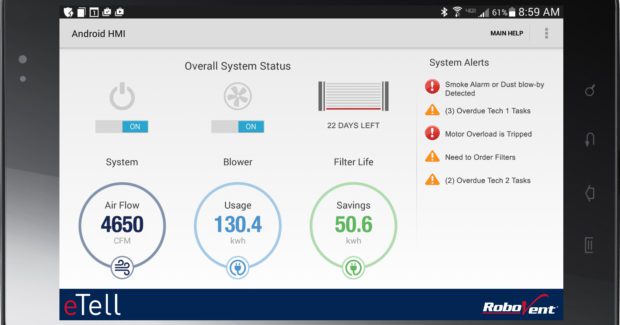

One area that can benefit from smart automation is air quality – and the technology already exists today. Smart, connected dust collectors use sensor data and computer algorithms to adjust their behavior in response to changing conditions. Instead of simply running continuously, these machines can adapt to the levels of particulates in the air, filter loading and other variables – and even predict future needs based on past usage behaviors. For example, our eTell™ control system can:

- Conserve energy by dynamically adapting blower speeds to compensate for particulate levels or filter loading;

- Adapt dynamic filter pulsing systems to particulate levels in order to maximize filter life;

- Predict filter life and maintenance requirements based on real-time performance data;

- Calculate energy use and adjust system settings to maximize energy efficiency based on actual use behaviors;

- Control safety features such as automated shut-down for fire prevention; and

- Notify users or repair technicians if attention is needed.

At the whole-plant level, devices like our eQ™ Air Quality Monitoring System continually monitor quality throughout the plant and control all air quality systems from a central server. Dust collectors are turned on when they are needed and off when they aren’t, saving energy and wear and tear on the equipment. Smart controls learn over time, so they know, for example, that particulate levels in a certain part of the plant peak in the middle of the shift, and will proactively adjust blower speeds to compensate at that time. By automating these functions, smart dust collectors improve equipment and filter life, reduce energy use, and reduce maintenance time and expense. Instead of performing routine preventative maintenance, companies can now focus on predictive maintenance, relying on the machines to tell them what is needed.

THINKING BIG: THE DATA-DRIVEN ENVIRONMENT

The big picture of environmental controls goes beyond just air quality. Ultimately, environmental systems will be connected so they can communicate and work together. That means everything – lights, HVAC systems, dust collectors and more – will be automated using real-time data. Coming next fall, our eQ360 will monitor light levels, noise levels, CO levels, temperature and humidity along with air quality. With this data at their fingertips, plant managers will be able to look at environmental issues in new ways. For example:

- How are different environmental factors correlated with productivity, absenteeism, accident rates or employee complaints?

- Can variations in productivity across plants or shifts be related to specific environmental factors?

- What’s the best way to balance energy savings and employee comfort?

Now, imagine all of this data feeding smart control systems that respond in real time and learn over time. These systems will be able to anticipate and respond to the needs of the humans in the building – perhaps even better than the humans can. The technology for whole-plant (or whole-company) environmental automation isn’t quite there yet, but it will be coming soon. When it does, you may start thinking about your environmental systems in a whole new way – or stop thinking about them at all. After all, they’ll be able to take care of themselves.