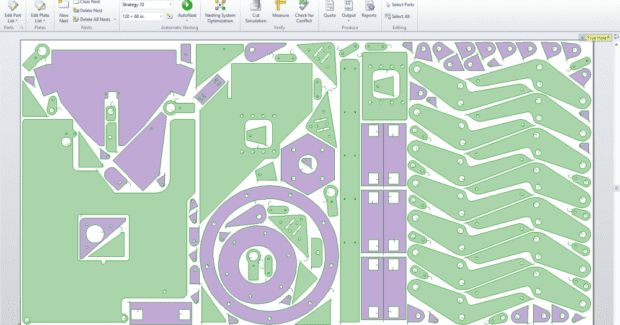

CAD/CAM Nesting Software Improves Automated Cutting Efficiency and Profitability

ProNest 2017 from Hypertherm contains more embedded cut process expertise in the NC code than any other software, allowing shops to leverage other cutting technologies.

Posted: May 20, 2016

Hypertherm (Hanover, NH), a U.S. based manufacturer of plasma, laser, and waterjet cutting systems, has announced a major version upgrade to its ProNest® advanced CAD/CAM nesting software for automated cutting. ProNest 2017 contains a number of improvements designed to make customers more efficient and profitable. New features include:

- Manual nesting improvements, including drag array, anchor part to cursor, and automatic bumping functionality for greater control and faster nesting.

- Color by part property that fills parts with different colors based on a designated attribute (name, priority, work order number, due date, etc.) and reports that show fill colors in part images making it easier to locate parts.

- Redesigned drill machine interface for plasma or oxyfuel machines that incorporate drilling, tapping, and other spindle operations to seamlessly tackle jobs directly in ProNest.

- Native 64-bit support allowing the software to take advantage of the extra accessible memory available on a 64-bit CPU/Operating System.

“The outcomes our customers expect as a result of using our CAD/CAM software drives us to deliver exceptional solutions so they may achieve more and do it more profitably. This software will deliver increased material savings, boost productivity, lower operating cost and improve part quality,” stated Derek Weston, the product marketing manager for CAD/CAM software products. “In addition, this software contains more embedded cut process expertise in the NC code than any other software, allowing our customers to leverage patented technologies like True Hole®, True Bevel™, and Rapid Part™.”

More changes to the nesting software family of products are also taking place as part of this major version release. The nesting software for cutting in production environments, formerly named TurboNest®, is now called ProNest LT. The nesting software for cutting in job shop environments, formerly NestMaster™, is now ProNest LTS. ProNest LT and LTS contain many of the features found in ProNest 2017. Users with an active Software Subscription can upgrade to the new version of their respective product at no additional charge and continue to receive unlimited technical support, and other benefits. For more information, please click here.

Hypertherm, Inc., 21 Great Hollow Road, PO Box 5010, Hanover, NH 03755, 603-643-3441, Fax: 603-643-5352, www.hypertherm.com.