Coolant-Through Tooling

By targeting the coolant stream as close to right place in the cutting zone as possible, coolant-through tooling systems can bring improvements that range from higher cutting speeds to better surface finish by effectively controlling chips and helping to optimize tool life and increase production. Here are some of the latest systems to consider.

Posted: May 10, 2016

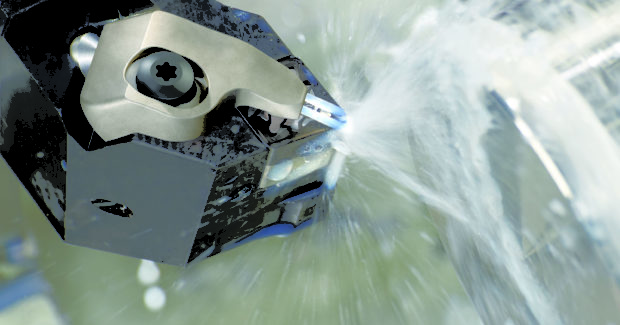

Powerful, Directed Coolant Boosts Productivity, Tool Life and Surface Finish

The Turn Precision Coolant delivery system from Walter increases tool life by 30 percent to 150 percent when machining stainless materials, high temperature alloys and steels.

Over and Under Coolant Helps Increase Machine Utilization for Effective Steel Turning

The unique CoroTurn 300 insert from Sandvik Coromant has excellent chip breaking capabilities and less carbide per edge to reduce the impact on the environment with less material to waste or recycle, and more edges for better inventory control.

Coolant-Through-The-Tool Drilling

Using the reCool attachment from Rego-Fix Tool on Suhner feed drilling units can increase surface cutting speed by 20 percent for higher chip removal rates and drastically reduced machine cycle time.

Coolant-Through High-Feed Face Mills and End Mills

Coolant-through ready cutter bodies from Techniks are made from high grade H13 tool steel that is precision ground for accuracy and feature an electroless nickel coating for longevity and rust resistance.