Getting Mobility & Smart Connected Devices Right on the Factory Floor

What is the appropriate size of a mobile device to use on the factory floor?

Posted: May 6, 2016

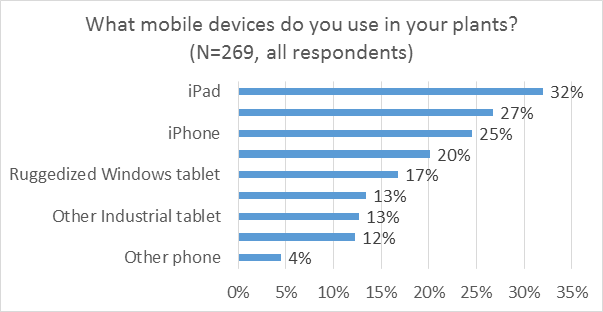

We were recently asked about the appropriate size of mobile device to use on the factory floor. The obvious answer to this is “it depends,” which is not helpful, but true. So we explored data generated from the mobile questions in a recent Industrial Internet of Things (IIOT) survey we conducted that deal only with generic devices: tablets, phones and similar tools for interacting with manufacturing software systems, such as Manufacturing Operations Management (MOM) and plant quality systems. Our survey results to date show that the deployment of mobile devices – indeed, standard ones such as the iPad and other tablets – is becoming the new norm in the shop (see Figure 1). Apple is clearly leading the way and all major platforms are well represented. Since most applications in this type of device use pure web-based interfaces, the manufacturer and operating system of devices are probably less important than the convenience.

WHAT EFFECTS CONVENIENCE?

Convenience is often translated as “what I am used to,” but a number of other important factors should really be considered:

- What do I use the device for? Data entry, looking at diagrams, work instructions, etc.

- Can I do my job when I have my device in hand, pocket or wherever?

- Who uses the device?

Generally speaking, the more generic devices tend to be used for a large number of different tasks, whereas wearable and small devices might be single-task oriented (we will return to this later). When considering the size of generic devices, there will always be compromises. System designers need to work with factory floor staff to learn what are the real needs are, as opposed to the “nice to have” features that look great but add little to efficiency and quality. In a complex aircraft assembly factory, for example, workers move around a lot and undertake extremely difficult tasks under little supervision, with only with their tablet as a means of communication and the sole source of information. In this case, size will focus more on functionality than mobility.

A full-sized tablet (or even a 13 in PC convertible into tablet) is likely to be a suitable tool for our intrepid aircraft assembler as they work all over the huge airframe. They will be able to read detailed engineering drawings, play 3D models to see how to assemble specific parts and – vitally – be able to record and sign off on everything they do. Access to design information, the ability to update the as-built record, and sign everything off are all achievable on a full-sized tablet. Clearly, trying to do all of this on a phone or small tablet would prove frustrating at best, perhaps dangerous if proper procedures could not be followed.

In many other less demanding cases, a full-sized tablet will be more of a hindrance than a help. We believe that phone-sized devices will be very useful for simple data entry and signing off work, but much more limited for instructions and help. Manufacturers should look at midsize tablets (or really big phones) as a compromise between portability and conveniences for a lot of general purpose tasks, because the size will be fine and they can still slip into the pocket of a pair of work trousers.

The scope for mobile devices goes far beyond the general purpose devices running HTML5 capable web browsers. Size, function and complexity can all be addressed by:

WEARABLES AND SPECIAL DEVICES

Technology on the factory floor is intended to help improve product quality, productivity and safety, among many other things. When new technology is introduced there is often a first mover’s tendency to try to do everything possible with the new toys. Wearables and smart devices are an extreme example of potential playthings. We already see examples of smart glasses, wearable bar code scanners, and positioning devices using simple Bluetooth that help to ease everyday tasks, such as scanning when both hands are full, checking details of components, and providing great help to supervisors and managers who want a different view on their mobile device, depending on location. All of our kids are quite comfortable using location-based services – let’s use them in our factories too.

IT IS NOT NECESSARILY EASY, BUT GET MOBILITY GOING

Mobile device connectivity and security must be planned in the context of a plant or enterprise system. Many manufacturers are starting to use their IIoT platforms to provide these vital services. However your shop does it, basic security – something that surveys show to be less solid than one might hope in the factory environment – becomes absolutely critical when a shop goes wireless and mobile. After security and connectivity come the first real steps of getting into mobile devices. Now is the time to incorporate one or two smart mobile devices to enhance the user experience. Consider size, but remember that it is functionality and productivity improvement that are the real measures of success. Mobile devices will drive improved business processes and more connectivity across the enterprise. It might even help people be more productive on the shop floor.