One Step Closer to the Factory of the Future

As the Factory of the Future learns how to manufacture parts as seamlessly as possible, portable metrology is making major inroads for machine control in large robots used for assembly operations that previously involved very expensive fixed tooling, multiple operators, and many days to accomplish these tasks.

Posted: May 3, 2016

Creating a highly accurate CNC machine using a Commercial-Off-The-Shelf (COTS) industrial robot has been on the industry checklist for years. There have been small scale examples of this concept, but none offered the accuracies required for small parts, nor could they be scaled up in size to accommodate large parts. Picture the potential of highly accurate inline robotic automation in a large-scale manufacturing facility, and all the scalable ideas that may be realized as well. Manufacturers could start building metal fabrication centers similar to how the automotive industry builds assembly lines. There could be rows of COTS robots doing welding, bending, milling, drilling, deburring and even buffing and polishing, all within normal shop floor conditions with no specialty machining centers required.

So what is blocking our progress? In short, today’s industrial robots are limited by their achievable accuracy. Many robot manufacturers do offer “high accuracy” versions of their robots. There are also many off-the-shelf robotic calibration solutions, but unless modified, they cannot achieve the required accuracies for a task. One such device is SARCA (SA Robot Calibration Appliance) from New River Kinematics (Williamsburg, VA), which enables almost any COTS robot to be measured through a series of poses with a high accuracy metrology device like a laser tracker. This process transforms a highly repeatable robot into an accurate machine.

ROBOT REBOOT

However, even with all of this great technology, a calibrated robot still has limitations. To start, the calibration is feasible if the robot is stationary. Once the robot is mounted to a 7th axis like a translation slide on an overhead rail, it is far more difficult to correct. The second core limitation is that compensation or correction is based on static point locations. In order to use the robot for any of the processes listed above; it must be used dynamically, not just in static poses.

Although the dream seems beyond our reach, not all hope is lost. There has been a major resurgence of interest in this concept focused around the Factory of the Future (FoF). Near the end of 2012, a €4.3 million program funded by the European Commission brought together eight companies from four European countries to build a “Megarob” system as described. The project’s focus was to develop a multi-functional robot to repair parts or tools and perform precision manufacturing on parts in excess of 32 ft to accuracies found in small-part production and well outside the positioning capability of standard industrial robots.

After three years of research and development, the Megarob effort delivered a prototype COTS robot on a ceiling-mounted overhead crane that can be used for milling, drilling, deburring, grinding, polishing, riveting, screwing, welding, painting, or quality dimensional control tasks. The flexible automated platform can be deployed for different tasks anywhere within its working volume, leaving the workshop floor completely clear. Megarob maintained the project’s targeted accuracy of less than 0.015 in over a 320 ft part or assembly. The potential applications are endless in industrial sectors such as aeronautics, marine, renewable energy, construction and civil engineering.

ENTER PORTABLE METROLOGY

At the heart of the groundbreaking Megarob technology is a 7DoF (seven degrees of freedom) laser tracker that precisely measures the end-effector of the robot in real-time and corrects its actual position based on the global coordinate system of the part. But here’s the quantum leap: this process completely removes the robot accuracies from the equation. The robot’s end-effector can now being driven at up to 1 kHz in real-time by the positioning accuracy of the laser tracker.

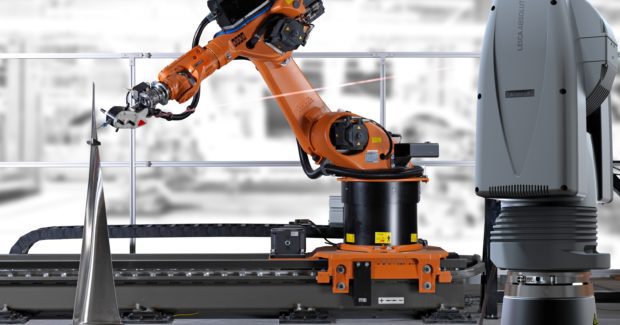

A portable Leica Absolute Tracker AT960 and Leica T-Mac (tracker-machine control sensor) were integrated into the platform to continuously monitor the robot’s movements. The measurement devices work in tandem to measure an artifact’s position and orientation in space. The 7DoF measurement capability integrates the tracking system’s technologically mature 1,000 Hz 6DoF data with low latencies and highly-accurate timestamps. The robot’s end-effector position and orientation are corrected up to a thousand times per second, ensuring it operates accurately along the provided toolpath.

In late 2015, Megarob was brought on-line and it has been a huge success. Its implementation is changing the way we think about large-scale, high accuracy automation solutions using COTS robots. Moreover, Megarob has also unearthed some weaknesses in this solution. First, a large industrial robot can only react to so much rapid data feedback. Secondly, not all robots perform the same in this situation. Quite simply, they were never designed to be used in this manner. Industrial robots are huge machines designed to do the same repetitive tasks again and again. They are very relatable machines, but mostly adaptable for point to point movements. The idea of making a robot accurate for dynamic movements, in particular fast dynamic movements, is a very challenging task for most manufacturers.

7DOF CLEARS THE HURDLE

A system has now been developed that offers both dynamic speed and robot independence based on the industry-first 7DoF laser tracker. This new technology essentially adds a critical time dimension to traditional 6DoF measurement data acquired by the laser tracker, which is made possible by interfacing LMF communications with industrial EtherCAT protocol. The machine control system can be synchronized accordingly and corrections can be applied in real time – even in dynamic robotic setups.

Rather than use the 1 kHz real-time data to control the entire robot, the 7DoF tracker is interfaced to a very fast end-effector. The change in philosophy is quite straightforward. The large industrial robot is used for the gross positioning of the device to an accuracy of within a few inches. The active tool (end-effector) then corrects for the difference between the robot’s actual location and where the specific task requires the end-effector to be positioned.

Because the active tool only needs to travel in a relatively small volume (±3 in to 4 in all directions), it can be designed to be very fast and extremely rigid. With multiple T-Mac sensors mounted on the active tool, the Absolute laser tracker can monitor the device’s actual position in any orientation. By combining laser interferometry for distance and photogrammetry for angular pose determination, the system can maintain incredible accuracies over very large volumes. Once the laser tracker locks onto the active tool, the machine control system synchronizes accordingly. The end-effector’s actual position in space is fed back to the active tool so its position can be corrected, and the TCP (tooling center point) is accurately positioned to the proper location.

THE TRAINING WHEELS COME OFF

By separating the real-time control of the robot into two steps, potential users and applications can be far less dependent on any specific robot or robot manipulation programs. In theory, a production facility could standardize on a single brand and model of robot and not have to worry about project-specific robot requirements. The same robot moving an inventory pallet on one end of the factory floor could also be used for drilling or milling operations at the other end of the facility. The fine detail work required for these tasks would be handled by the robot’s end effector driven by real-time 7DoF coordinate data generated from laser trackers.

Metrology-assisted machine control and robotic guidance is a reality for plant operations today. Manufacturers have begun to use large COTS robots on rails for assembly operations that previously involved very expensive fixed tooling, multiple operators, and many days to accomplish these tasks. The Factory of the Future movement will compel companies to automate the assembly of parts or materials, and develop new approaches to manufacture parts as seamlessly as possible. The 7DoF active tool technology is paving the way towards the FoF, and we are working with key integration partners to build custom end-effectors for factory use today. This industry milestone will enable advanced manufacturers and technology leaders to pioneer configurable robotic systems with multi-tasking capabilities, and cross it off their checklist.