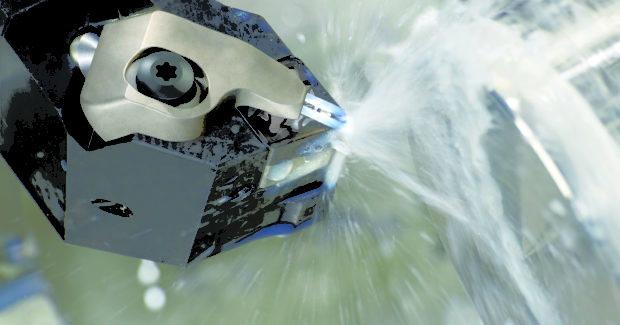

Powerful, Directed Coolant Boosts Productivity, Tool Life and Surface Finish

The Turn Precision Coolant delivery system from Walter increases tool life by 30 percent to 150 percent when machining stainless materials, high temperature alloys and steels.

Posted: May 9, 2016

Walter USA, LLC (Waukesha, WI) introduces Walter Turn Precision Coolant, a powerful and targeted coolant delivery system that produces a direct coolant supply through the insert clamp and along the flank face of the insert. The result is a 30 percent to 150 percent tool life increase (depending on material and coolant pressure) for stainless materials, high temperature alloys and steels. This system directs coolant precisely at the cutting edge providing greater lubrication, cooler inserts, and improved chip control, beginning at pressures as low as 150 psi. The positive effects increase with pressure, particularly at pressures above 580 psi. This can result in cutting speed improvements of up to 100 percent while maintaining the same tool life. Along with greater productivity, this improves surface finish with less peripheral zone work hardening, boosts process reliability and benefits energy efficiency.

This new system is aimed primarily at ISO material groups P, M, and S, with a pressure range of 150 psi to 2,250 psi that makes the system suitable for 95 percent of all machine tools in use today. The coolant delivery system features three coolant connection points: coolant hose connections at the back of the tool and under the head, and a direct coolant transfer port for VDI connections. Higher pressures up to approximately 4,500 psi are also possible, especially for aerospace applications.

Walter has also introduced new parting blade adaptors for BMT/DO machines that ensure precision cooling of both the insert and the parting blade, thus improving chip control and tool life, and helping to increase productivity. With this design, the coolant flows through the adaptor directly into and through the parting blade to the cutting zone. An O-ring seal ensures that the coolant transfers efficiently and with no loss of pressure. In addition, for particular applications the adaptors can also be used with external cooling, either alone or in conjunction with internal cooling. This is done simply by adjusting the coolant nozzle. Installing the new parting blade adaptors requires only a single bracket, whether the adaptors are installed in the standard position or overhead.

As an additional benefit, the adaptor has adjustable center height for each individual workpiece within a range of ±0.020 in (±0.5 mm) that allows an exact center position to be set on any workpiece, without additional tasks. The precision coolant supply ensures excellent chip control and minimized tool wear. Machine productivity is increased by minimizing downtime to clear large chip volumes. The robust holder is designed to allow machining in any position required, minimizing vibration during operation. The new BMT/DO parting blade adaptors work with a coolant pressure of 145 psi to 1160 psi, which means that they can be used on virtually any machines that feature a BMT interface.

Walter is a global leader in the metalworking industry with over 90 years of experience in precision cutting tools for milling, drilling, turning, boring and specialized tools that improve process reliability and increase productivity. With regional headquarters in Waukesha, the company markets its Valenite, Titex, Prototyp and Multiply brands through a strong network of distributors and field engineers across subsidiaries in the U.S., Canada, Mexico, Brazil and Argentina.

Walter USA, LLC, N22 W23855 Ridgeview Parkway West, Waukesha, WI 53188, 800-945-5554, www.walter-tools.com/us.