CAD/CAM Increases Milling Efficiency in Roughing and Extends Tool Life

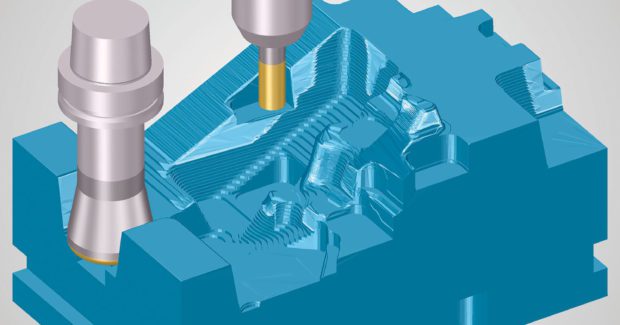

Version 4.0 Release 2 CAD/CAM software from Tebis is especially well-suited for rough machining of deep cavities and hard material.

Posted: June 29, 2016

Tebis America Inc. (Troy, MI), a leading software supplier specializing in CAD/CAM systems for design and manufacturing servicing the tool, die, mold, aerospace and automotive manufacturing industries, has announced the launch of its Version 4.0 Release 2 CAD/CAM software that is especially well-suited to the rough machining of deep cavities and is effective for hard material machining as well.

In roughing, the depth of cut and the best utilization of cutting data ensure fast and cost-effective manufacturing while keeping tool costs low. The tool path automatically adapts to the geometry without full-width machining. The integrated re-roughing counteracts the formation of larger steps in steep boundary areas. These areas can be machined from bottom to top with a smaller depth of cut.

Extensive tests have been performed on this version. “The best way to machine a component depends on a wide range of factors,” explains Helmut Vergin, the product manager at Tebis. “These include the specific geometry, the material, and the available tools and machines. Technology parameters such as cutting data and feed rates must be adapted accordingly to the machining. That is why it was important to conduct the tests with tool and machine manufacturers.” As a technology partner, the company provides advice on how to best implement and combine the new software to achieve the best possible results.

Tebis America, part of Tebis AG (Munich, Germany), develops CAD/CAM systems for tool, die and mold manufacturing, primarily for automobile and aircraft manufacturers and their subcontractors from the styling, model making, tool and mold manufacturing sectors. They supply turnkey installations and also provide a full suite of 40 software modules focusing on increasing their customers’ ability to reach higher profits through consulting, implementing new technology, training and support.

Tebis America, Inc., 400 East Big Beaver Road, Troy, MI 48083, 248-524-0430, www.tebis.com.