Gas Shield for Welding Titanium Prevents Oxidation

Weld Trailing Shields from Huntingdon Fusion Techniques ensure that the weld remains under an argon gas shield until the metal has cooled below its oxidation temperature.

Posted: June 29, 2016

When welding titanium using the GTAW/TIG process, the gas shield from the welding torch needs extending for protection from oxidation and for productivity. Although welders will use a larger than normal gas cup to provide a big surface area of protection, this still limits the speed at which they can move the welding torch.

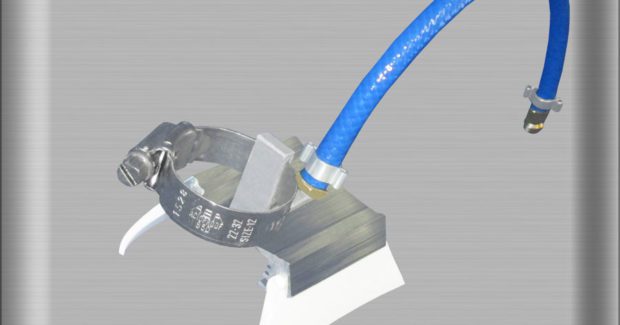

To provide additional surface protection and in order to weld faster, Huntingdon Fusion Techniques (HFT®; Carms, UK) manufactures a range of Weld Trailing Shields® to effectively lengthen gas cups fixed onto and dragged along behind the welding torch to ensure the weld remains under an argon gas shield until the metal has cooled below its oxidation temperature.

https://youtu.be/UtJGYZbMj8E

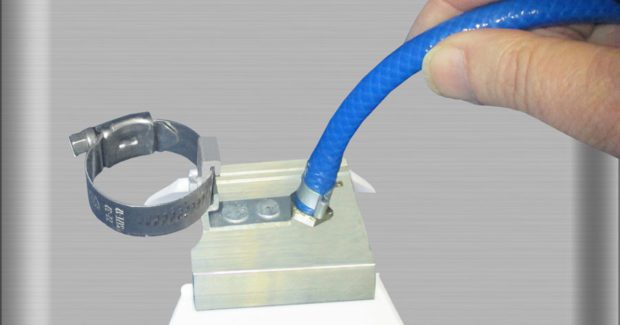

“These professionally manufactured shields are usually around 100 mm to 150 mm long as standard, with specials for automatic welding being as long as 450 mm (17 in), although many applications require smaller shields. With the lack of commercially available small shields, shops have been required to fabricate their own using innovative methods. However, we have now designed and developed the smallest shield available at only 40 mm (1.6 in) long,” stated Ron Sewell, the chairman for HFT.

These lightweight devices simply attach to all standard manual or automatic TIG/GTAW and Plasma/PAW welding torches and will at least double the area being shielded as well as allowing access to tiny spaces. For manual welding, the welder finds that with this low cost tool there is no difficulty in dragging it along the surface being welded. One further benefit is that it carries the welding torch at 90 deg to the weld.

With automatic welding machines it is possible to raise the welding speed dramatically and enjoy the major benefits of automatic welding. Weld Trailing Shields are also manufactured in flat format for sheet metal welding.

HFT’s worldwide exclusive distributor network can be found by clicking here.

Huntingdon Fusion Techniques HFT, Burry Port, Carms, SA16 0BU, UK, 44-1-554-836-836, 877-431-1311(U.S.), Fax: 321-984-8455, www.huntingdonfusion.com.