All-In-One 3D Measurement and Inspection

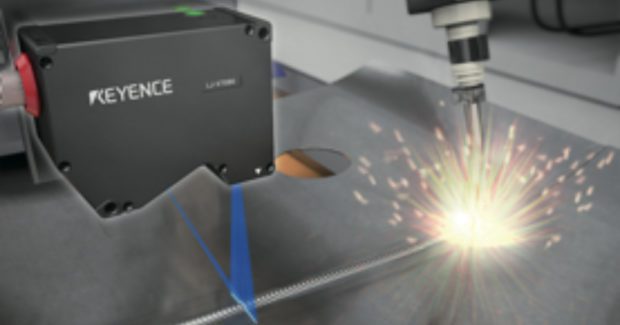

The XG-X vision system from Keyence combines high-resolution 3D height images with ultra-high speed processing for inspection that cannot be done with conventional laser profiling or traditional 2D imaging.

Posted: June 18, 2016

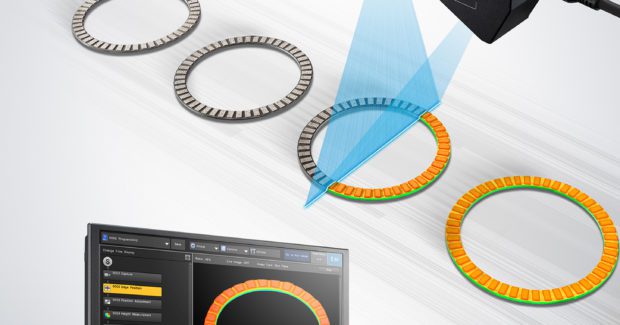

Keyence Corporation of America (Itasca, IL) released the first all-in-one 3D measurement and inspection package that features the best laser profiling technology and image processing algorithms. The brand new XG-X vision system makes 3D setup and programming easier than ever with a new user interface and programmable encoder. The XG-X combines high-resolution 3D height images with ultra-high speed processing enabling inspection that cannot be done with conventional laser profiling or traditional 2D imaging. This system provides the “Three Keys to 3D Success,” which are:

Best Laser Profiling Technology

- 64,000 profiles per second

- High-resolution height profiling

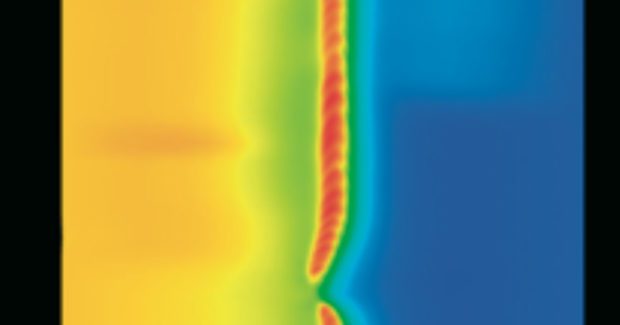

Most Powerful 3D Image Processing

- Real-time Vibration Correction

- Simultaneous 2D/3D imaging

Ideal Proportional Image

- Easily synchronize dedicated encoder

- Up to 150,000 pulses per revolution

Keyence has steadily grown since 1974 to become an innovative leader in the development and manufacturing of automation equipment worldwide, including automation sensors, static eliminators, barcode readers, measuring instruments, vision systems, laser markers, and digital microscopes.

Keyence Corporation of America, 1100 North Arlington Heights Road, Suite 210, Itasca, IL 60143, 888-539-3623, Fax: 201-930-0099, marketing@keyence.com, www.keyence.com.