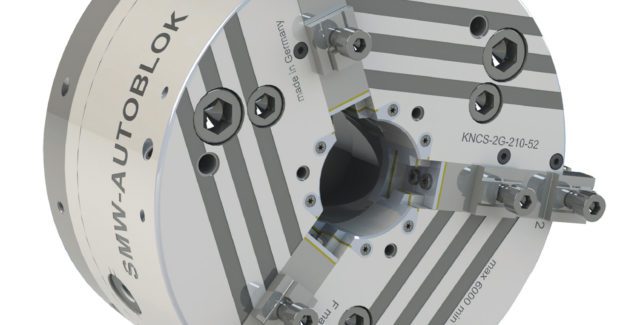

Sealed Quick Jaw Change Chucks

Ideal for mass production operations, KNCS-2G next generation of quick jaw change chucks from SMW Autoblok provide extra defense against chips, lubricant and other debris, and only require lubrication every third shift.

Posted: June 24, 2016

In Booth W-1400, SMW Autoblok (Wheeling, IL) will be featuring their KNCS-2G next generation of quick jaw change chucks. The KNCS-2G offers the same superior flexibility, minimal set up times, and high repeatability as the original KNCS-N, but with added protection and efficiency, making it ideal for mass production applications. With its optimized lubrication system, the KNCS-2G is designed to save time and money in maintenance and upkeep. The original KNCS-N needed lubrication every shift, but the optimized jaw guide ways of the 2G make lubrication necessary only every third shift. Additional channels and grease pockets in the jaw guide ways help the chuck operate for longer, while seals in the chuck body and base jaws of the KNCS-2G provide an extra defense against chips, lubricant and other debris.

The chamfered guide ways of the KNCS-2G allows for jaws to be changed in less than 60 seconds, making this chuck ideal for machines that require frequent setup changes. The ability to interchange jaw with the standard KNCS-N offers added flexibility by allowing existing master jaws to be used without sealing. These features, in combination with a low loss of grip force due to centrifugal force, make this chuck well suited for high-speed applications.

SMW Autoblok, 285 Egidi Drive, Wheeling, IL 60090, 847-215-0591, Fax: 847-251-0594, lrobbins@smwautoblok.com, www.smwautoblok.com.