Stationary Beveling Machine for Hands-Free Beveling of Plate and Bar Stock

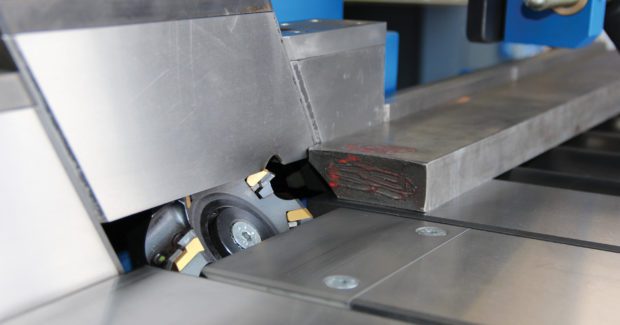

The high speed MMB 500 stationary beveling machine from Saar-Hartmetall produces very high quality bevels on small, medium and large aluminum, steel, and stainless steel plate and bar stock workpieces.

Posted: June 30, 2016

Saar-Hartmetall USA LLC (Covington, KY), has announced the addition of a new stationary beveling machine to complement their existing line of equipment for weld preparation and beveling. The new MMB 500 is suitable for processing small, medium and large aluminum, steel, and stainless steel plate and bar stock workpieces and is designed for hands-free operation that is capable of providing a variety of bevel angles between 30 deg and 60 deg (25 deg and 55 deg).

This high speed stationary beveling machine produces a very high quality bevel and is suitable for a multitude of beveling applications. It features separate, variable speed motors for feed-rate adjustment and a milling head with eight, 4-sided indexable inserts. The MMB 500 is the “big brother” to the MMB 400 Stationary Beveling Machine that has been in service and well established in the industry for many years. The machine increases beveling capabilities to include larger bevels and heavier duty applications.

“We are pleased to be able to add this very capable machine to our extensive line of products that will help shops to be more productive,” states Iwan Antonow, the executive vice president of the company. “This addition addresses a demand for machines that produce bigger bevels on heavier workpieces and allows us to be a one-source supplier for weld pre-processing and beveling equipment.”

Saar-Hartmetall offers a full line of tube scarfing tools, peeling tools, beveling tools, and a variety of cutting tools used in metal fabrication and the tube and pipe industry. From their sales office and warehouse in Covington, they provide products, customer support and service to North American shops.

Saar-Hartmetall USA LLC, 1009 Mary Laidley Drive, Covington, KY 41017-9528, 859-331-8770, www.shmusa.com.