BeAM Machines Establishes U.S. Operations

BeAM is partnering with Fives Machining Systems on large-part LMD machine sales and maintenance, with plans to manufacture their machines in the U.S.

Posted: July 27, 2016

BeAM Machines, Inc. (Hebron, KY), the first European manufacturer of metal 3D additive manufacturing machines using laser metal deposition (LMD) technology, has established operations in the United States and is working with the support of the Fives Group (Paris, France) subsidiary, Fives Machining Systems Inc. (Hebron, KY), to serve the U.S. market that has become a world leader in additive manufacturing.They also plan to manufacture their large-part metal additive machines in the U.S.

Tim Bell, a ten-year veteran of additive manufacturing, will serve as the general manager and vice president of business development for this U.S. subsidiary. “We believe we have a better additive solution for customers in the aerospace, defense, and additive manufacturing markets, and we are looking to advance as a leader in these markets,” stated Bell. “The U.S. market is fairly mature when it comes to additive manufacturing and we believe our highly advanced technology will be well received due to its industrial approach and support.”

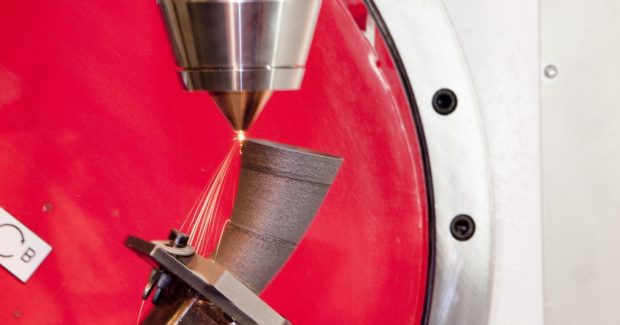

A spin-off from a 30-year-old French Laser research center, BeAM is built on LMD and CNC technology. LMD feeds laser melted metallic powder through a deposition nozzle to create a layer-by-layer part construction with perfect CNC-controlled dimensions. As a general rule, any material that can be laser welded is potentially suitable for use with LMD. Their LMD machines support a wide range of materials, such as stainless steel, titanium nickel alloys, cobalt chromium and more, and are available with a range of standard and custom nozzles for most every industrial application.

Their fully integrated LMD machines are CE-certified, modular, upgradable, and deliver high-performance through longevity and accuracy in a controlled atmosphere with a secure powder environment.

“We aim to accelerate the development of the LMD market and we’re looking to lead LMD industrial machine manufacturers in developing new applications in the field of manufacturing and repair,” stated Bell. “Our machines have the capacity to direct 3D print high-value parts, add functional shapes and/or functions to those parts, as well as perform repairs on parts previously rendered as scrap, using the CLAD® (Direct Laser Additive Construction, Construction Laser Additive Directe in French) process.”

“CLAD revolutionizes the maintenance market in the aerospace and other sectors by drastically reducing the cost and time of repairs,” stated Emeric d’Arcimoles, the chief executive officer of BeAM. Well established in the aeronautics, space and defense fields, BeAM was the first manufacturer of LMD machines to obtain the highest aeronautical-quality standards certification to repair critical parts.This certification has effectively extended the lifetime of key parts from 10,000 hours to 60,000 hours, saving customers valuable time and money.

BeAM machines for the U.S. will be manufactured at the Fives’ machine tool facilities located in the U.S. and follow a solution-oriented approach that offers an open invitation for unique and collaborative partnerships with AM centers in the U.S. to advance the AM industry as a whole.

www.beam-machines.com, www.fivesgroup.com