An Ideal Alternative to Wiping Dies

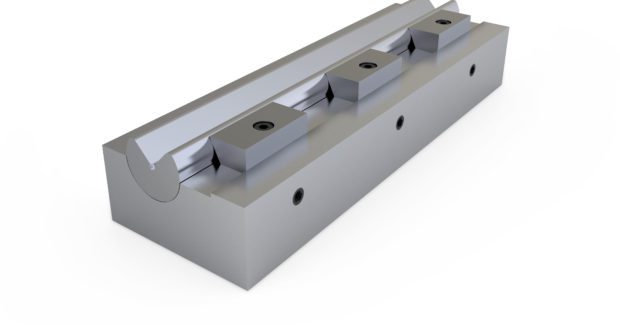

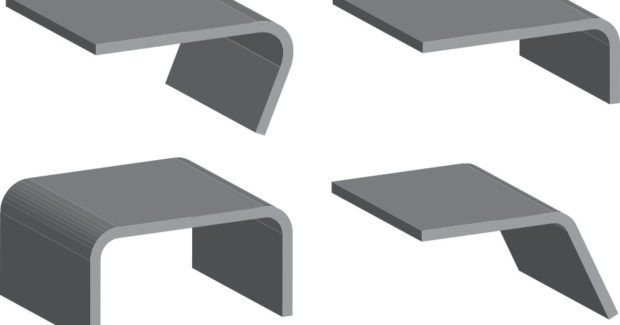

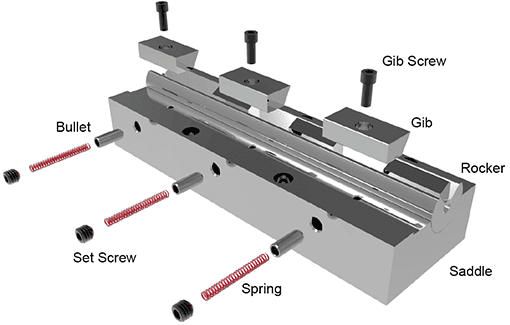

The Posi-Bend self-contained rotary bender from Dayton Lamina cams the material without undesired distortion, sliding, or marring.

Posted: July 26, 2016

Dayton Lamina™ Corporation (Dayton, OH), a leading provider to the tool, die, metal stamping and mold industries, offers a new line of rotary bending solutions. The Posi-Bend™ rotary bender is an ideal alternative to wiping dies and is engineered to be less complex and lower cost than traditional wipe tooling. Rotary bending provides consistent metal forming without wasting material on tests and re-grinding. The self-contained rotary bender cams the material without undesired distortion, sliding, or marring.

Extensive inventory is available for same day shipments for standard product. More product information and custom orders are also available with short lead-times by clicking here and here.

Dayton Lamina is a MISUMI Group Inc. (Tokyo,Japan) company with approximately 1,500 employees in factories throughout the U.S., including OH, IN, MI, WI, as well as in Canada, Mexico, Portugal, Czech Republic, Japan and China (majority-owned joint ventures). They are a leading Western market supplier of die and mold components with brands that include Dayton Progress, Danly, Lamina, IEM,and Lempco. MISUMI is a global supplier of factory automation products, die and mold components and other industrial products.

Dayton Lamina Corporation, 500 Progress Road, PO Box 39, Dayton, OH 45449, 248-489-9122, Fax: 248-553-6842, www.daytonlamina.com.