Metal Additive Manufacturing for Industrial Production

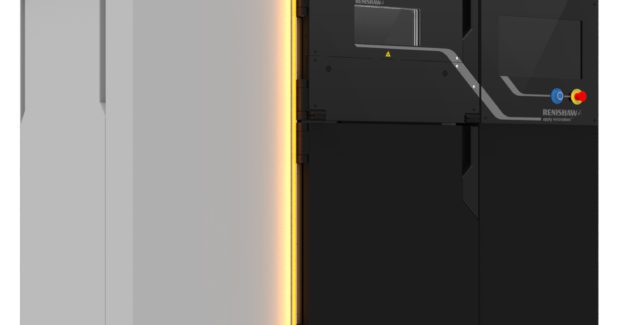

The RenAM 500M from Renishaw is ideal for serialized production of complex metallic components directly from CAD using metal powder bed fusion technology.

Posted: July 31, 2016

In Booth E-5509, the RenAM 500M from Renishaw Inc. (Hoffman Estates, IL) is designed and engineered with serialized production in mind to build complex metallic components directly from CAD using metal powder bed fusion technology. The RenAM 500M is first in a family of products based around Renishaw’s optical systems and control technology and offers unparalleled engineering with efficient, ergonomic design and safety features, as well as intuitive and automated capabilities. The company has core skills in optical engineering, motion control and manufacturing from over 40 years of producing industrial high-technology products. The RenAM 500M builds on the advantages of the Renishaw AM system platform, with over ten years of metal powder bed fusion development and experience and state-of-the-art manufacturing expertise. The machine manufactures parts within the 250 mm x 250 mm x 350 mm build volume (9.84 in x 9.84 in x 13.77 in) and utilizes a high powered ytterbium fiber laser to fuse fine metallic powders together creating functional three-dimensional parts.

In-line sieving allows powder to be recycled and re-used in a single process under an inert atmosphere, reducing user interaction and turnaround time. Metallic powder is loaded into the machine hopper at the front of the system and sieved ultrasonically. Any un-melted material is returned to the hopper and passes through the ultrasonic sieve before being processed. Sieved powder is pneumatically transferred in a flow of high purity argon gas into the powder delivery silo. The RenAM 500M features a patented high capacity twin SafeChange™ filter system enabling builds to run for long periods in a stable and controlled atmosphere. Filters capture process emissions safely and efficiently and the machine’s intelligent control system actively senses the filter’s condition and redirects the gas circuit to a clean filter before conditions deteriorate. Powder sieving and recirculation are automatically carried out within the compact system, reducing the need for manual handling and exposure to materials, which provides increased safety and sustained quality of the metal powders.

The RenAM 500M is ideal for industrial production application, specifically serialized production. Each system is intended to be dedicated to a single material type for a lights-out manufacturing environment and provides a higher level of automation compared to the AM250 and AM400 platforms. Inherently intuitive, the large 480 mm (19 in), durable touchscreen and machine control software allows for ease of navigation through every process step. Based on a Windows® operating system with a dedicated user interface, large icons show the build set-up workflow for clear and straightforward operation. Specifically developed to accept future upgrades – a characteristic prevalent throughout all of Renishaw’s product lines – ensuring that every machine provides a pathway to future performance updates.

Renishaw Inc., 5277 Trillium Boulevard, Hoffman Estates, IL 60192, 847-286-9953, susan.wilm@renishaw.com, www.renishaw.com/additive.