Top of the Line Finishing on Steel, Stainless Steel

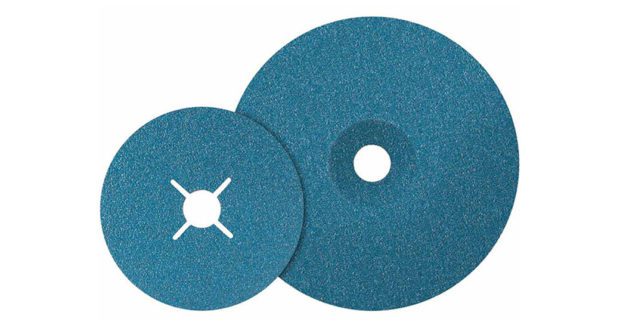

The Topcut sanding disc from Walter Surface Technologies uses a new formulation of blue Zirconium grain blend to remove material 50 percent faster and with a longer lifespan.

Posted: July 30, 2016

Walter Surface Technologies Inc. (Montreal QC / Windsor, CT), a global industry leader in surface treatment technologies, introduced the new and improved Topcut™ sanding disc, one of the latest additions to their industry-leading finishing solutions. The new sanding disc now features a new formulation of blue zirconium grain blend to remove more material, faster. “This new blend contains a higher concentration of Zirconium, making it the highest performing Zirconium grade disc on the market,” stated Jonathan Douville, the product manager for Surfox, E-Weld and Finishing Solutions at Walter. “The new and improved discs remove material 50 percent faster than the previous model, and also have a longer lifespan.”

The new grain blend is designed for finishing applications on steel and stainless steel and offers maximized stock removal on any given surface. The disc also guarantees cooler sanding so that the metal will not overheat. “The cooler sanding helps to preserve metals, especially the heat-sensitive material, and will result in a beautiful, finished product,” added Douville.

Topcut comes in exclusive 50-pack protective packaging designed with humidity control to preserve the wheel’s physical properties until ready for use. This means performance is kept at the highest standard possible. Discs are also available in the standard pack of 25.

Walter Surface Technologies provides innovative solutions for the global metalworking industry, from high performance abrasives, power tools and tooling to industrial parts washing systems, cleaners, degreasers and lubricants. Founded in 1952, the company is established in seven countries throughout North America, South America and Europe. International headquarters is in Montreal and U.S. headquarters is located in Windsor.

Walter Surface Technologies, Inc., 810 Day Hill Road, Windsor, CT 06095, 800-522-0321, www.walter.com.