Application Specific Thread Whirling Inserts in Less Than Three Weeks

GenSwiss offers quick delivery of Utilis inserts for thread whirling that improves thread surface finish and can be utilized for threads smaller than 12 mm diameter in medical devices.

Posted: August 29, 2016

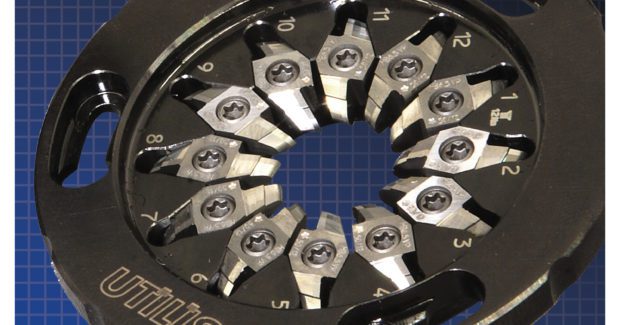

Thread whirling allows for improved thread surface finish and can be utilized for threads smaller than 12 mm diameter in medical devices. Genevieve Swiss Industries, Inc. (GenSwiss; Westfield, MA), a top source for tools, accessories and assistance for Swiss machining, offers less than three week delivery times for Utilis® application specific inserts used with Utlilis thread whirling rings and attachments in today’s Swiss type machines. Utilis offers a standard line of whirling inserts for popular threads such as standard metric, ANSI, and ISO Buttress style threads for most medical applications. The whirling rings are available with 9 inserts or 12 inserts for high output thread production.

“This industry leading delivery capability stems from Utilis’ manufacturing investment to service global whirling demand and a dedicated staff that is the most knowledgeable in the industry developing new technologies. And quite frankly, we too bring strong application experience and product depth to expedite the process,” says Scott Laprade, the marketing manager at GenSwiss, which is also the exclusive North American representative for Louis Belet SA precision carbide cutting tools and PCD tipped milling tools. With a heritage of being supplier to many of the legendary Swiss watch manufacturers, Louis Belet offers highly focused niche products for medical and micro manufacturing applications. Precision carbide tools include Micro Drills, Coolant-Thru Drills offered in application specific geometries, and select coatings that are proven to deliver clean, high precision results with more holes, and extended tool life for reduced manufacturing costs.

For example, Expert 370 series drills for stainless steel incorporate newly engineered cutting and coating parameters that result in greater productivity levels, less burrs and overall higher quality holes. For brass applications, Expert 1820 series micro end mills are optimized to deliver higher metal removal rates, superior surface quality and all important greatly extended tool life. Carbide end mills are available as micro, square, ball nose, plus engraving mills, saw blades with variable tooth geometry and full radius forms and a broad selection of PCD end mills and PCD drills for a wide range of precision machining applications. Louis Belet has over 6,500 standard catalog offerings.

Genevieve Swiss Industries, Inc., 6 Old Stage Road, Westfield, MA 01085, 413-562-4800, Fax: 413-562-4802, sales@genswiss.com, www.genswiss.com.