Automation Systems

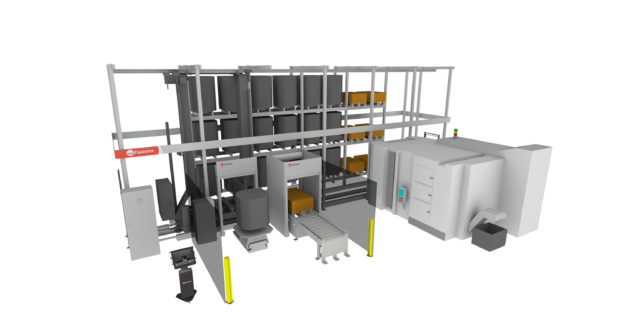

The expandable FMS ONE Flexible Manufacturing System, FPC-1500 Flexible Pallet Container system and Multi-Level FMS System from Fastems help shops integrate cells with other plant-wide systems to evolve into a fully digital Industry 4.0 factory.

Posted: August 6, 2016

Fastems, LLC (West Chester, OH) will have their automation systems exhibited at three different booth locations: First, they will unveil their brand new expandable FMS ONE Flexible Manufacturing System in Booth S-8500 of Okuma America. Next, their FPC-1500 Flexible Pallet Container system will be integrated with two Niigata machining centers in Booth S-8936 of SNK America. At both locations, visitors can see these fully automated cells using the latest generation MMS5 Manufacturing Management Software that is considered one of the industry’s most versatile FMS control systems. It can grow from the cell to ultimately integrate with other plant-wide systems across industry’s spectrum, helping shops evolve to a fully digital Industry 4.0 factory. Third, a fully featured scale model of their Multi-Level FMS System will be exhibited in their own Booth S-9178.

Fastems personnel will be on hand at all three booth sites to demonstrate and explain these systems, along with helping visitors assess whether increasing automation in their shops makes sense, and how different degrees of automation can be achieved with this wide-breadth of automation system offerings that includes variety of extendable and flexible manufacturing systems, robotics and global support services. These “open” automation systems can be incorporated with virtually any modern CNC machine tool and auxiliary equipment brands. Typical applications range from joining two machine tools together with a Flexible Pallet Container (FPC), such as the FPC-1500, to highly sophisticated, factory-wide flexible manufacturing systems, such as the new FMS ONE. With an FPC, shops can begin automating just one machine tool and often realize a return on investment quickly. As a demand increases, they can extend the FPC to accommodate up to three machine tools. The FMS ONE is a modular and flexible system that offers a wide range of MMS5 options to match user needs. It handles the logistics and material management and is suitable for several common machine tool types.

The scale model Multi-Level FMS System will be controlled by a full-size MMS5 software operator interface with capabilities that can extend from a single manufacturing cell to a fully integrated shop-wide system. The MMS5 can also be integrated with other manufacturing plant software, such as ERP and MRP systems, and is fully compatible with MT Connect. In addition to the hardware and software of the automation systems, staff will also educate visitors about “Fastems 8760 Service” global support services, which indicates how the service team stands behind its customers each hour of the year – 8,760 total – for the entire life of the system. Among the many highlights in this newly enhanced program include remote technical support, worldwide 24/7 availability, active system monitoring to help shops achieve maximum uptime, comprehensive training programs, a dedicated customer portal to quickly see at a glance the status of the system, and much more.

Fastems LLC, 9850 Windisch Road, West Chester, OH 45069, 513-779-4614, Fax: 513-779-4638, www.fastems.com.