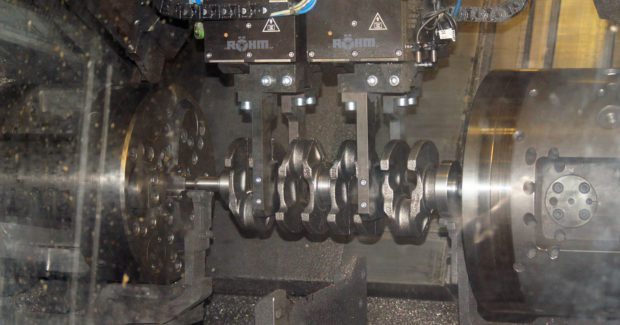

Complete Machining of Crankshafts in Just One Setup

Automation meets clamping technology in the combination of a shaft chuck, steady rest and gripping technology from Röhm that is ideal for machining and transport of crankshafts in different manufacturing stages.

Posted: August 3, 2016

In Booth W-2528, under the motto “Automation meets clamping technology,” (Suwanee, GA) will be showing complete solutions for crankshaft machining, putting their strengths as a system supplier into play. Their individual components interact perfectly with each other and ensure efficiency and effectiveness in the everyday production process. For this reason, Röhm is showing the combination of a shaft chuck, steady rest and gripping technology for the machining and transport of crankshafts in different manufacturing stages. The shaft chuck can be converted in just a few minutes from highly accurate centric clamping to balancing clamping for clamping blanks. Depending on the desired machining process, this allows very flexible use.

Extended clamping arms make high machining forces possible. The clamping arms can be retracted without reclamping to be able to execute complete machining on the ends of the shaft. In the process, the workpiece is moved by the face drivers. It is transported reliably from machine to machine by the gripper technology that works reliably and is almost maintenance-free. This is an important factor in the fully-automated manufacturing of crankshafts because the gripping situation for the complex geometry of crankshafts is not simple. It is ultimately supposed to be just as reliable to grip short crankshafts for three-cylinder engines as it is for long crankshafts for twelve-cylinder engines. The shafts are gripped in the main crankshaft bearings without the unloaded balancing weights getting in the way of the gripping process. This is ensured by long gripping jaws that have to be guided reliably.

In the harsh production environments of the automobile industry, these benefits and typical Röhm reliability and long service life are highly important. Users also enjoy the distinct service-mindedness of Röhm, which offers a perfect overall package as a reliable partner from engineering through production.

Röhm Products of America, 2500 Northlake Drive, Suwanee, GA 30024, 770-963-8440, Fax: 770-963-8407, www.us.roehm.biz.