What You Need to Know Right Now to Improve High-Volume Micro Manufacturing

Opportunities abound for shops to cash in on the ever-growing micro machining market, but the differences between different types of micro tools vary from those found in standard tooling. Here are some insights into the extra care and know-how needed to achieve success and build a successful reputation as a reliable supplier of micro machined parts.

Posted: August 24, 2016

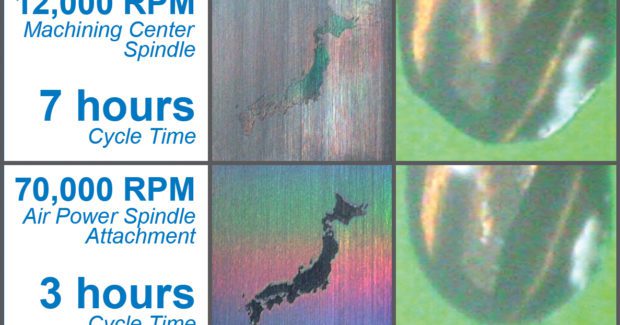

- On a standard machining center which leads to high cycle time, poor surface finish and premature cutter wear.

- Using a spindle speeder which enables the tool to be ran at the proper speeds, which leads to excellent surface finish, drastically reduced cycle time, and no noticeable tool wear.

The growing need for production of miniature parts and features in medical and dental applications – as well as mold making, fiber optics, automotive, and other industries – has taken us beyond more sluggish EDM and laser processes. Such tiny tooling and part features are, by nature, challenging to manage. And at production-level volumes, achieving consistent quality is even more difficult. If you’re looking for ways to improve productivity with micro cutting tools, here’s what you need to know about . . .

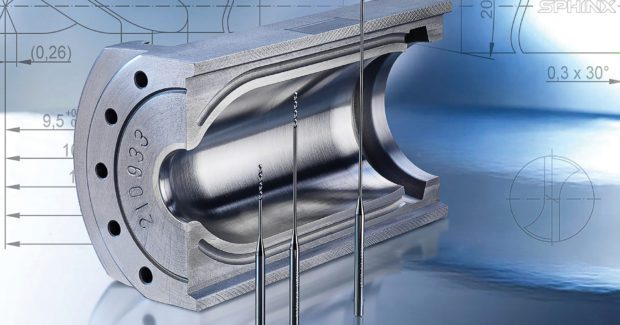

. . . WHAT MICRO TOOLS ARE

We consider tools with diameters under 3 mm to be micro tools. It’s important to note that these tools aren’t simply smaller versions of their macro counterparts. They have geometric considerations all their own and you must understand them. For example, our Ø1mm Sphinx drill can run at 80xD. But this is only possible because, by design, the cylindrical shaping extends further down the tool, closer to the tip, to facilitate pecking and maintain strength.

. . . CUTTING EDGE RADIUS

Edges on micro cutters are not proportional to those of macro cutters – it’s just not possible. Because of the duller edge, the energy required for micro cutters relative to the MMR can be up to 10x higher than their larger version. Because of this, we recommend using the shortest micro tool possible to avoid deflection.

. . . COATINGS ON MICRO TOOLS

With such miniscule features, even a coating can negatively affect performance. This is because the coating fills in valuable flute space for proper chip evacuation, which is absolutely critical in these applications.

. . . USING COOLANT

Use coolant only when absolutely needed and take special care when you do. These tiny tools are more sensitive than standard ones and even liquid flow can weaken their structure in the cut.

. . . FEED PER TOOTH WITH RESPECT TO MILLING

Often overlooked in micro milling, it’s critical that feed per tooth equals the cutting edge radius.

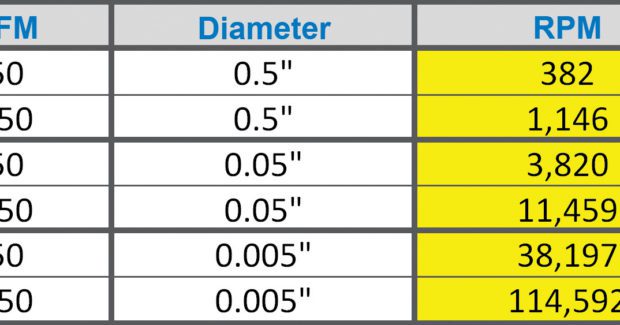

. . . THE EFFECTS OF CHIP EVACUATION ON FEED RATE AND RUN OUT

Chips and small tooling do not get along all that well. While trying to compensate for low spindle speeds with tools that have more flutes may help reach your ideal feed rate, chip evacuation will suffer. Determining the appropriate chip load – as close to the cutting edge as possible – allows you to operate at the highest possible spindle speed, speeding up the cycle improving surface finish and lessening the chances of built up edge.

. . . BUILT UP EDGE

Because such little stock is being removed, rubbing (instead of actual cutting) can occur which increases the chances of built up edge. This results in more required force and higher chances of deflection and/or early failure.

. . . THE IMPORTANCE OF THE RIGHT TOOL HOLDER

With requisite speeds for successful micro machining exceeding 60,000 rpm, quality micro cutting tools themselves are not enough to achieve success. You must also control important factors like dynamic runout and balance. You must have the appropriate holder, not only to ensure quality work, but also to preserve the life of your tools. When choosing a holder, for instance a micro collet chuck, keep in mind helpful attributes like a symmetrical design, a perfectly concentric collapse of the collet around the cutter, and a ball bearing raceway nut with precision-ground threads. Upfront costs may be higher, but preserving these specialized cutting tools will, without a doubt, save you money in the long run.

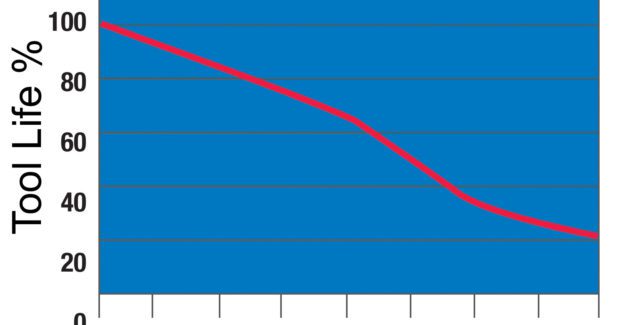

. . . TOOL WEAR

When runout occurs, the edge most affected takes over most of the cutting. The uneven wear leads the tool to failure much quicker than if the tool rotates about the centerline as intended. In one customer application, drilling into a steel workpiece 0.590 in deep with a 0.118 in diameter carbide drill in a holder with 0.00008 in runout accuracy produced 2,300 holes. A holder with 0.0006 in runout accuracy was only able to produce 800 holes. In this scenario, the shop could save hundreds of dollars a month in carbide costs – as well as labor costs due to less tool changing – by making one smart tool holder choice.

. . . HOW BALANCE CHANGES DURING A CUT

The balance itself does not change as speed increases, however, the forces it creates increase exponentially alongside speed. And at the high speeds required for micro machining, you’ll quickly see the impact.

Opportunities abound for shops to cash in on the seemingly ever-growing micro machining market. But it’s not as simple as increasing spindle speeds or using smaller tools. Miniature tooling is innately different than the more standard macro tools. The differences between the different types of micro tools vary from what you see in the standard tooling world. As such, the practice requires extra care and know-how in order to achieve success and build a reputation as a reliable supplier of micro machined parts. Whether you’re already a player in the micro game or are just starting to consider throwing your hat in the ring, hopefully these insights will help you grow and improve your work.