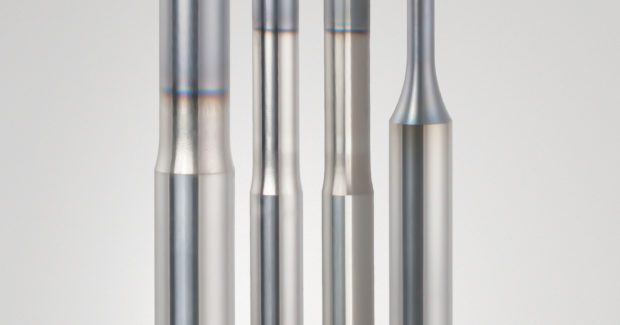

Solid Carbide End Mills for High-Feed Milling

SN 200R/400R/500R solid carbide end mills with 2-, 4- and 5-flute options from Niagara Cutter allow medical parts manufacturers to achieve maximum productivity when performing face, slot and select plunge milling operations.

Posted: August 29, 2016

Niagara Cutter, LLC (Troy, MI), a subsidiary of Seco Tools, LLC (Troy, MI), has expanded their range of end mills for high feed milling applications. Their new SN 200R/400R/500R solid carbide end mills with 2-, 4- and 5-flute options allow medical parts manufacturers to achieve maximum productivity when performing face, slot and select plunge milling operations. Niagara applied the latest design and grinding developments to these SN 200R/400R/500R end mills, which feature a defined radius (rp) that helps direct radial cutting pressure axially up into the tool holder and spindle. This increases metal removal rates in deep pocket and long reach applications, and allows for more stable operation, less vibration and reduced wear on the machine tool. As such, manufacturers can lower their production expenses and stay more competitive.

SN 200R/400R/500R end mills also feature an AlTiN coating that allows these end mills to achieve long, predictable tool life in milling applications involving high temperatures and abrasive workpiece materials, such as titanium and pH stainless steels. The coating also helps lower operating costs by eliminating the need for coolant in high-temperature situations. Cutting diameters for the SN200R (2-flute) range are available from .063 in to .500 in for 3xD, 5xD and 7xD lengths. The SN400R (4 flutes) range spans .125 in to .500 in for 3xD, 5xD and 7xD lengths, while the SN500R (5 flutes) range covers .375 in to .500 in for 3xD lengths.

Optimal application of the SN 200R/400R/500R cutters is dependent on several factors, from the age of the machine tool being used to the part size being cut. For example, the cutters can run at maximum feed rates when applied alongside a highly rigid, modern machine tool. Proper programming is also important to ensure optimization of the cutter path. With the right CAM program, it is possible for the SN cutters to perform select plunge milling applications. Niagara can assist manufacturers in developing the most appropriate high-feed machining strategies for their operations.

Niagara Cutter, LLC, 2805 Bellingham Drive, Troy, MI 48083, 248-528-5220, Fax: 248-528-5600, customerservice@secotools.com, www.secotools.com/us.