Cost Effective Fiber Laser Cutting of Tubes

The affordable, fully automatic FLTA series fiber laser tube cutting system from Horn Machine Tools offers a lower cost solution for high quality laser cutting.

Posted: September 2, 2016

Horn Machine Tools, Inc. (Madera, CA), a world-class manufacturer and distributor of CNC tube bending machinery, now offers both flat sheet and tube laser cutting machines that utilize highly efficient fiber laser technology and are configured in four different models which can be customized to fit the customer’s requirements. These lasers feature high quality components found on many of the other more expensive machines on the market: the fiber laser power source is from IPG Photonics, the laser cutting head is from Precitec, the servo motor system is from Yaskawa, and the control system is from Power Automation. The machines utilize Lantek software to facilitate programming and nesting functions. All of the major components on these machines have worldwide support and are readily available.

“The market has been seeking a lower cost solution for laser cutting for some time now,” noted company president Kent Horn. “Until recently, this valuable manufacturing process has been out of reach for many fabricators because they can’t justify the high cost. We can now provide both a high quality CNC tube bender and laser cutter for much less than the laser would cost from other sources.” The high production, fully automatic tube laser model FLTA loads the tube into the cutting area and processes the cut parts without assistance from the operator. There is also a semi-automatic machine for entry level buyers which have all the same cutting capability, except that the operator provides minimal assistance to position the tube into the tube chuck. Both machines have an unloading table to handle the cut tubes being discharged from the machine.

https://youtu.be/VYrMh9jQtKc

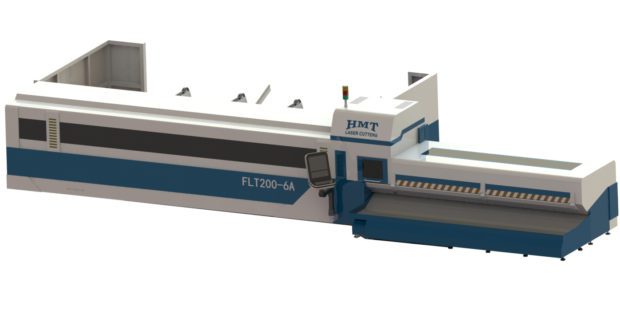

The flat sheet cutters are configured in two formats: the model FLSA is a conventional 5 ft x 10 ft flat sheet laser cutter with a double exchange sheet handling system, and the model FLTS is a combination machine which combines a 5 ft x 10 ft flat sheet cutter along with a tube spindle for processing tubular shapes. The combination machine is an excellent choice for fabricators with both flat sheet and tube cutting requirements that don’t have the volume to justify buying two separate machines.

Horn Machine Tools, Inc., 40455 Brickyard Drive, Madera, CA 93636, 559-431-4131, sales@hornmachinetools.com, www.hornmachinetools.com.