Band Saw Blade Cuts Stainless, Tool Steels, Titanium Alloys, Nickel-Based Alloys

The new X-Series M51 Tooth Edge Microstructure for band saws from Eberle increases hardness and toughness values for increased productivity, longer blade life, lower cost per cut, and less downtime and blade changes.

Posted: October 31, 2016

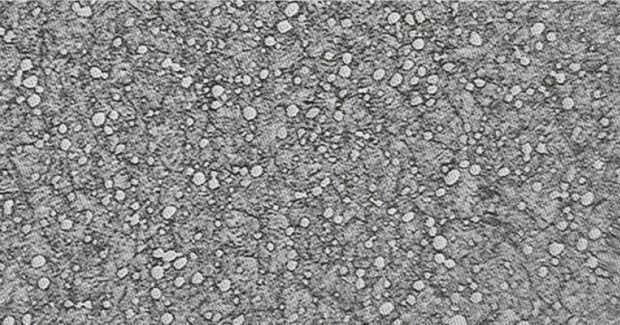

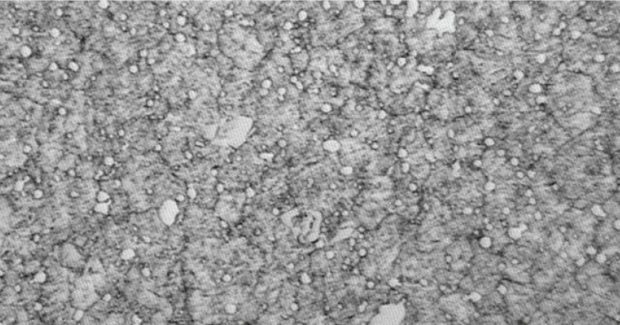

In Booth C-46077, Eberle America, Inc. (St. Louis, MO), a manufacturer of band saw blades and metalworking fluids, will feature their new X-Series M51 Tooth Edge Microstructure for band saws. According to the manufacturer, their Heat Treatment process offers a significantly more consistent and uniform microstructure than a conventional M51 tooth edge microstructure. Comprised of powdered metal, the X-Series M51 Tooth Edge offers increased hardness and toughness values and high capability of heat and wear resistance. It’s ideal for cutting mold steels, stainless steels, tool steels, titanium alloys and nickel-based alloys. The X-Series features an advanced, uniform microstructure and a micro-resistant, stable cutting edge for increased performance. Benefits include increased productivity, longer blade life, lower cost per cut, and less down time and blade changes.

Eberle America, Inc., 6311 Ronald Reagan Drive, Suite 174, Lake St. Louis, MO 63367, 314-406-1102, www.eberle-america.com.