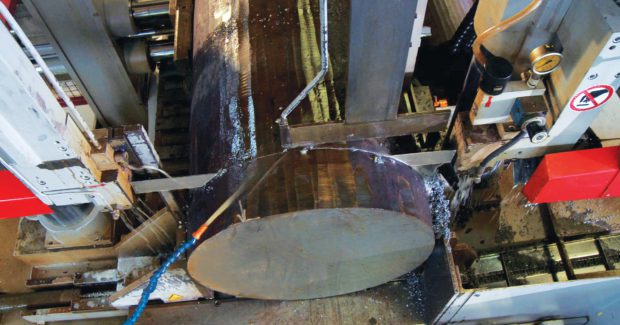

Band Saw Blades for Heavy Duty Cutting

Primalloy Saw Band Saw Blades from Starrett provide superiority in overall wear and operating life without the expense of carbide-tip solutions. It minimizes blade replacement to cut costs for steadier production.

Posted: October 11, 2016

In Booth C-16028, Starrett Company (Athol, MA) will display their Primalloy Saw Band Saw Blades for heavy-duty cutting applications. The cutting performance of the high-speed steel is greatly increased through alloying with cobalt and Vanadium. These alloying elements substantially increase the heat resistance as well as the wear resistance. The Primalloy Saw provides superiority in overall wear and operating life without the expense of carbide-tip solutions. With Primalloy Edge and Extended Life Treatment (EXT) functionality, the Primalloy Band Saw minimizes blade replacement, thus cutting costs resulting in steadier production. Other features include:

- Longer operating blade life due to tooth tip chemistry

- Increased cutting accuracy

- Improved efficiency over the all-purpose M42 HSS Edge Band Saw

- Cost-effective cutting solution for steels with low machinability

- Three times the Vanadium content dramatically increases wear resistance over competitive products

- Ground teeth are effective for the hardest steels and alloys of all dimensions

- 10 percent cobalt tool steel cutting edge provides excellent heat resistance

- EXT applied to alloy steel backing material ensures maximum fatigue life

The Primalloy Edge provides higher edge hardness, up to HRc 69, over competitive M42 products, and faster cutting rates due to its aggressive 12 deg tooth form. Primalloy will also beneficial on machines that are not rigid enough for carbide tip products.

Starrett Company, 121 Crescent Street, Athol, MA 01331-1915, 978-249-3551, www.starrett.com.