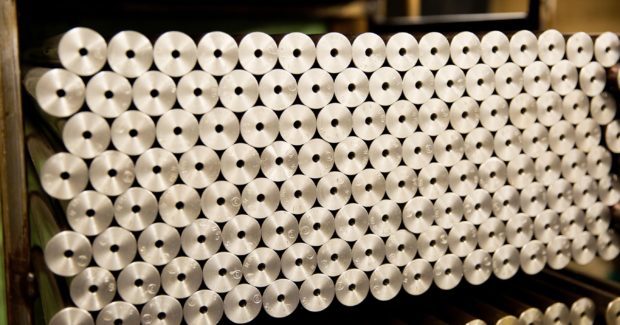

Gun Barrel Honing System Hits Target

Take a look at how this honing machine outshoots hand lapping in the manufacture of precision rifle barrels at Pac-Nor Barreling.

Posted: October 10, 2016

Manufacturing precision rifle barrels has always been something of an art that involves hand lapping of the bore surface twice, before and after the rifling profile is cut or swaged in by a rifling button. In fact, a bright, hand-lapped bore is considered one of the hallmarks of a precision rifle barrel, despite the inherent variations from manual work done by people who get bored and tired from the monotonous chore. Pac-Nor Barreling, Inc. (Brookings, OR) set its sights on this issue more than a year ago and hit the X-ring with the newly developed HTE honing machine from Sunnen Products Company (St. Louis, MO) that has all but eliminated Pac-Nor’s pre-rifling lap, which is the more difficult and time consuming of the two laps.

The shop is also producing as many custom barrels as ever, but with a slightly smaller staff. “Our objectives with the hone were to build a better product with less labor, and the honing machine has exceeded my expectations,” said Casey Dichter, the production manager at Pac-Nor. “The hone produces a consistency in bore diameter that is head and shoulders above lapping, within two to three millionths of an inch end-to-end when it’s really dialed in. This, in turn, improves the consistency of the rifling process by minimizing variation in the depth of the grooves. We still finish lap after rifling, but it’s easier because we just polish off the fine crosshatch finish that may be left after honing and rifling.”

Pac-Nor Barreling is a true custom manufacturer that caters to bolt-action rifle shooters. The company’s principle markets are law enforcement, military, competitive shooters and hunters. Started in 1984 by avid shooter and company president Chris Dichter, Pac-Nor is now in its second generation under his son, Casey. In addition to barrel manufacturing, the shop will install the barrel on a customer’s action, or add features such as muzzle brakes or fluting on bolts and barrels etc.

The shop runs two shifts per day. A day shift of ten people produces 30 to 40 custom barrels of different calibers in 416R stainless or chrome-moly steel. A night shift of three people produces one type of barrel – about 50 AR-15 barrels per day for a rifle OEM. The process starts with cutting and facing premium bar stock, followed by gun drilling, done by four Pratt & Whitey twin-spindle machines and an Eldorado CNC twin spindle. After reaming, the barrels are gaged for size. Depending on the condition of the reamer, 0.0004 in to 0.0007 in of material is left in the bore. This must be manually lapped out or honed out to final size for rifling.

“Everyone who works here has done hand lapping,” noted Dichter. “It’s an unpleasant job, particularly if the reamer is starting to get dull. Lapping may take 10 minutes to 45 minutes, depending on the caliber of the barrel. We tried to shorten this, but when chatter marks get ‘ironed’ into the surface by the rifling button, the finish lap is even longer and more difficult, so there is no advantage. With lapping there is also potential for variation, simply because it’s a manual process. Lapping can also be a production limiter, and in our region we have a very small labor force to draw on when we want to grow.”

The shop had explored honing in the 1990s, but re-visited the idea when the HTE honing machine was introduced in 2014. The HTE is a horizontal machine tool that can hone small-bore rifle barrels with a diameter range of 0.150 in to 0.790 in (4 mm to 20 mm) and lengths up to 60 in (1,524 mm). Designed specifically for long small bores, this machine features an extremely sensitive drive and tool feed system that provide maximum protection against tool overload/breakage. Tool specific force limits and run settings are stored in the touch-screen PC control, allowing the system to sense tight sections in the bore and correct them automatically.

Sunnen also developed a new Long-Bore Tool (LBT) that is designed to take on industry’s most difficult honing challenges in small bores of .17 caliber rifle barrels. The tool quickly removes reamer marks, waviness, tight spots and other imperfections left by upstream processes. The LBT utilizes metal-bond diamond or CBN superabrasives for high productivity, long life and fast cycle times. Precision machined of through-hardened tool steel, the LBT can produce bore accuracies of 0.000027 in (0.0006 mm) for diameter, roundness, and taper – from first part to last.

Honing is an ideal replacement for hand lapping barrel blanks before rifling. It quickly removes reamer scratches and surface waviness without labor-intensive hand lapping. A typical 600 grit abrasive can produce a 6 microinch Ra to 10 microinch Ra (0.15 µm to 0.25 µm) finish in a reamed barrel blank. By producing a consistent bore diameter (±0.0001 in or less), parallelism, roundness and surface finish end to end, honing yields more consistent performance from rifling buttons and cutters, resulting in a constant groove depth. The ideal bore geometry reduces distortion of the bullet shape for improved gyroscopic stability in flight.

“We are currently honing about 80 percent of what we make and will do more as we acquire the tools in different calibers,” added Dichter. “We have learned the quality of our reaming now does not need to be as critical because we have the hone. Although there is a tradeoff in cycle time and abrasive cost for additional honing, we are still able to run our reamers two to three times longer than when we lapped alone. With a hand lap, the time and effort increase when the reamer is getting dull.”

After honing, the barrel is inspected again before rifling with a pull-button. Pac-Nor makes its own Accu-Twist carbide rifling buttons and can provide different rifling styles, including polygonal, per their customer’s choice. A button is attached to a rod and the rod is pulled through the barrel. The shop’s hydraulic rifling machine utilizes a CNC-machined twist bar with a helix angle that matches the twist rate requested by the customer. The final twist rate is confirmed afterward using a Barrel-Scan electro-optical twist measurement system.

The barrel is then stress relieved in a tempering furnace, followed by contouring of the outer shape and final, finish lapping of the bore. “During the finish lap, you can really tell the difference between a bore that was honed before rifling and one that was lapped,” said Dichter. “You can easily sense any remaining tight or loose spots in the bore. The diameter uniformity and roundness of the honed bore are superb. The lap also feels different in a honed bore.”

In competitive shooting, where winning scores may be separated by thousandths of an inch, a few millionths of an inch improvement in the uniformity of a Pac-Nor barrel may make a big difference for a skilled shooter.

Pac-Nor Barreling Inc., 9299 Overlook Road, Brookings, OR 97415, 541-469-7330, pac-nor.com.