Wind of Change May Reroute the Future of Electric Cars

Reduced gas spending and environmental impact are big with electric cars. But instead of refilling, the need to pull over for recharging has still limited them. What if that changed? Take a closer look at a new concept that is pushing the limits of what is known today.

Posted: October 26, 2016

Electric cars have a lot to offer in terms of reduced gas spending and environmental impact, but the negative tradeoff has been the need to pull over to recharge rather than refill. But what if that changed? Robert Yost thinks it can. Yost is the founder of energy company American Wind, Inc. (Huntsville, AL) and inventor of the MicroCube wind turbine. Using a “Wind Wall” of his patented MicroCubes, he plans to drive cross-country in a Ford C-Max Energi electric car without stopping for energy beyond food and sleep. Yost believes that his Wind Wall will generate 2,800 watts per hour and keep the lithium-ion battery charged throughout the drive. If successful, the impacts of his MicroCubes could reach farther than any road trip, because he will have found a way to generate power more efficiently without cluttering the country with turbines and charging stations, introducing energy alternatives for housing and industrial environments as well.

So where did his idea come from, and how was it brought to life?

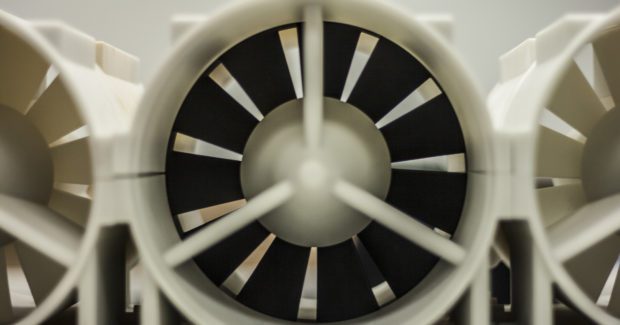

It all began with an Alabama tornado in 2011. In the storm’s aftermath, Yost sat on his back porch and watched as a pedal fan spun like a top in the eerie calm. As an engineer with a background in aerospace, he was struck by the energy potential waiting to be unlocked in micro form. So he founded American Wind in 2012 and started work on his designs. The resulting MicroCubes are 9 in x 9 in x 9 in wind turbines with multiple airfoils to capture more wind flow through the unit, improving the torque needed to generate power. Though this concept is common enough, Yost’s patented design has achieved an unprecedented level of efficiency to set it apart and can generate power in wind speeds as slow as one mile per hour.

The creation of this design was made possible through 3D printing via an on-demand parts manufacturing service provided by Quickparts (Atlanta, GA). “Using their additive manufacturing system, we were able to short-circuit the traditional process from concept to design to prototype to low-rate production in a quarter of the time it would have taken with more conventional processes,” notes Yost. Using a variety of DuraForm materials, he was able to match component functions with the desired material properties to efficiently manufacture his design without long lead times. The surface finish and fine details of DuraForm PA suited his assemblies, whereas the increased strength and high heat resistance of DuraForm GF (glass-filled) was a better match for the generator units. Finally, the turbine blades were produced with DuraForm HST Composite, a stiff material with high thermal properties.

Through his design and iteration process, Yost was able to optimize the wire routing within the case and between stators, as well as maximize the spool configuration and assembly process for the magnetic wire that generates electricity. Each time it came to 3D printing, he achieved strong, durable and flexible parts and assemblies that were indistinguishable from injection molding in all aspects but timeline. “On-demand manufacturing enables us to explore what works and what doesn’t work on a production part,” explains Yost. “We can make multiple changes and print those changes without investing thousands of dollars in molds or machining parts out of expensive materials.” And he can do it in a quarter of the time. “We are not breaking any laws of physics with the MicroCube,” smiles Yost. “But we are pushing the limits of what is known today.”

American Wind, Inc., 4900 University Square, Suite 1, Huntsville, AL, 35816, 256-319-0360, robert.yost@americanwindinc.com, www.americanwindinc.com.