Aluminum Extruder Reaps Profits from Innovative Temperature Measurement

Check out how this innovative pyrometer from AMETEK Land delivers high accuracy in a three-in-one capability for extrusion press exit, extrusion press quench zone and strip mills at Sapa Profiles UK.

Posted: November 1, 2016

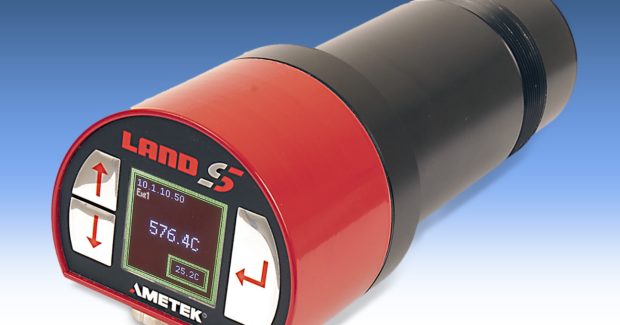

SAPA Profiles UK (Sheffield, UK), a leading producer of aluminum extrusions, has installed new SPOT AL EQS (SPOT Aluminum Extrusion, Quench and Strip) pyrometers from AMETEK Land (Dronfield, UK) at their plant in Tibshelf, Derbyshire, which is now reaping major production efficiencies and performance benefits through accurate measurement of the temperature of low and variable emissivity aluminum. This innovative pyrometer delivers high accuracy in a three-in-one capability for aluminum applications, including extrusion press exit, extrusion press quench zone and strip mills.

The Tibshelf plant supplies a large portion of their extrusions to the highly controlled automotive industry, which means the aluminum being processed must be cooled at an exact quenching rate to achieve the highest quality metallurgical properties. If this is achieved, the process provides greater confidence that the extruded profiles will meet the required structural properties in subsequent testing. In the past, the Tibshelf plant found it challenging to measure the lower end of the temperature range and sometimes had two separate thermometers to cover the wide spectrum. The advantage of SPOT AL EQS is that it covers temperatures from 200 deg C to 700 deg C (392 deg F to 1,292 deg F) within one highly effective instrument.

“Using this pyrometer at the press exit and after the quench has enabled us to continue to meet the exacting standards of our automotive customers,” said Cristiano Baiano, a senior automation engineer at SAPA Profiles UK. “The pyrometer gives us the ability to take accurate measurements at very low temperatures, which is essential to ensure product quality and performance. We now have all of the available data that our operators need to make informed decisions. An added benefit was that this instrument was very simple and straightforward to integrate into our control system.”

The plant required the ability to not only take fast and accurate temperature measurement readings in real time, but also to provide their operators with vital diagnostic information about what is happening throughout the extrusion press exit and quench process. The shop now has the ability to trend data over time, via a direct digital connection to the PLC. This gives operators a much better overview of the process performance, compared to using real time readings alone. They also can remotely trigger the LED sighting from a PLC and adjust the position of the quench exit instrument remotely.

“With precision control of extrusion conditions, we have minimal to no temperature variation for each extrusion length or from extrusion to extrusion, resulting in repeatable reliable material production with even metal quality and strength,” adds Baiano.

The SPOT AL EQS is specifically designed to work within low emissivity environments where regular pyrometers might struggle to provide accurate and reliable readings. Utilizing the latest cutting-edge design detectors, combined with the most-advanced data processing algorithms, this instrument is not only an extremely accurate and repeatable pyrometer with an industry-leading response time, but it also offers the ability to customize and tune the algorithms for made-to-order applications and specific aluminum grades.

https://youtu.be/61zYFT_N9xY

“This revolutionary new pyrometer is designed for even greater accuracy and convenience, which means the same pyrometer type can be used at all positions in the aluminum extrusion process,” explains Richard Gagg, the Global IR product manager for AMETEK Land. “SPOT AL EQS can make a huge difference to product quality and performance for shops where accurate temperature measurement at both ends of the spectrum is vitally important. It is a very user friendly, intuitive system that has been specifically designed to be easy to integrate within existing control systems. The high ambient temperature rating of 70 deg C allows the pyrometer to be used in many locations without the need for additional cooling.”

Incorporating the latest digital communication systems, the SPOT AL EQS can be configured remotely through a dedicated webserver. With Power over Ethernet capabilities, it will communicate data over Ethernet to any web browser or via Modbus TCP-IP, Modbus TCP, DHCP, http, udp and ICMP to ensure that along with its traditional 4-20mA / 0-20mA output signal, the pyrometer can be easily integrated into any plant control infrastructure.

The instrument can be operated straight out of the box by just one person, providing greater convenience and ease of use. If the sensor is in an inaccessible location, SPOT AL EQS provides remote viewing and motorized focus to verify alignment and ensure a high level of accuracy. A built-in camera aids alignment, and, combined with a green LED, allows the user to position the measurement point in the optimal location to avoid any ambient lighting reflections. Data from SPOT AL EQS is available remotely as snapshots using free SPOT Viewer software or standard web browsers.

Sapa AS, PB 81 Sentrum, 0101 Oslo, Norway, +47 2241 6900, info@sapagroup.com, www.sapagroup.com.

AMETEK Land, Stubley Lane, Dronfield, UK, S18 1DJ, +44 (0) 1246 417691, Fax: +44 (0) 1246 410585. land.infared@ametek.co.uk, www.landinst.com.