Power-Off Pneumatic Rod Lock for Cylinder Clamping

The fourth-generation Amlok RLI power-off pneumatic rod lock from AME is ideal for clamping cylinders and other machine tool holding applications.

Posted: November 8, 2016

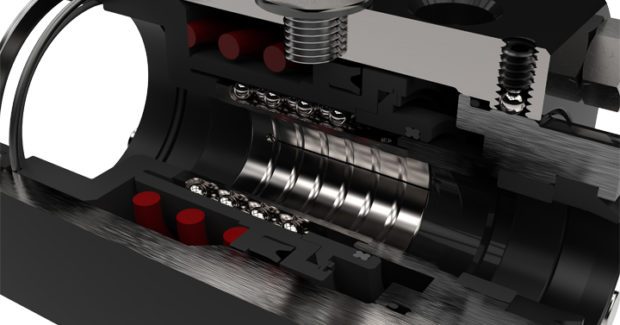

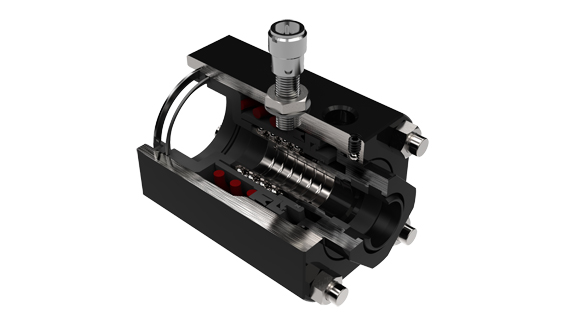

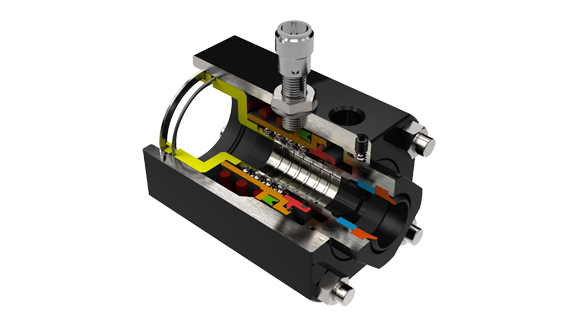

Advanced Machine & Engineering Co. (AME; Rockford, IL), a leading manufacturer of stand-alone and NFPA cylinder mount pneumatic rod locks for machine tool operations, offers the Amlok RLI power-off pneumatic rod lock. This basic lock unit is part of their RLN and RCH rod lock product line. The RLI Metric (ISO 6431) series complements their standard NFPA line. This fourth-generation lock is the culmination of 18 years of manufacturing and marketing of pneumatic and hydraulic rod locks.

https://youtu.be/ekHpvXM8KHE

The rod lock’s standard features include anodized aluminum construction, a heavy-duty clamp system and power-off clamping. The standard seal material is carboxylated nitrile. The unit uses dry-filtered air, has a release pressure ranging from a minimum of 4 bar/60 psi to a maximum of 8 bar/120 psi. The operating temperature ranges from 10 deg F to 180 deg F. Maximum rod tolerance is +0.000 in/-0.002 in. Rod lock options include stainless or electroless nickel-plated housing, viton seals, wiper scraper and sealed versions. The lock mounts to standard ISO 6431 cylinders or can be stand-alone using MXO, MF1, MF2 and MS1 mounting configurations.

The Amlok RLI is available in various sizes for rod diameters of 16 mm, 20 mm, 25 mm, 32 mm and 40 mm, and cylinder and bore diameters from 40 mm to 160 mm. Holding forces range from 200 lb/890 N to 2,450 lb/11 kN. The RLI power-off pneumatic rod locks are particularly-well suited for clamping cylinders and other machine tool holding applications.

Advanced Machine & Engineering Co., 2500 Latham Street, Rockford, IL 61103, 815-962-6076, Fax: 815-962-6483, info@ame.com, www.ame.com.