3D Printing a Spacecraft Valve Body in Titanium

Printing a part of this size in titanium in such a short time was something that could not have been achieved had the part been machined out of a billet.

Posted: December 20, 2016

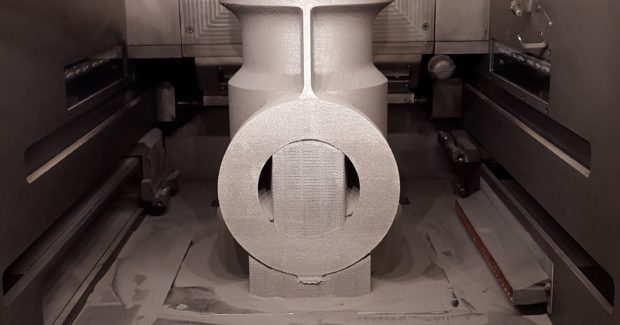

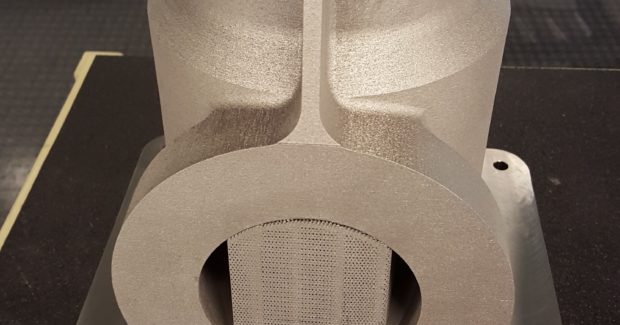

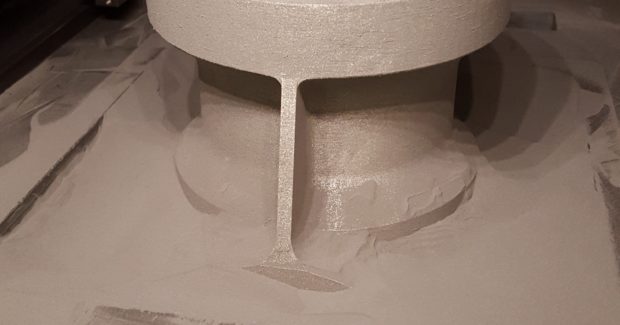

Progress continues to advance in the size limitations of the build chamber and other challenges that come with metal 3D printing of large titanium parts used for their strength and light weight in aerospace/aircraft applications. A 3D printed titanium aircraft component that measures 12.21 in x 8.74 in x 8.66 in diameter is the largest part to date built in an SLM280HL selective laser melting system with dual 400 W lasers. This technology made it possible to build a part of this size in a relatively short time frame compared to conventional manufacturing. The standard build plate size for machines of this class is 250 mm x 250 mm. But the SLM 280, with its increased build plate size at 280 mm x 280 mm, makes larger sized parts possible.

Advancements in 3D printing using titanium are particularly critical because the material is normally very hard and thus subject to cracking due to high residual stresses, which poses the real challenge. While the geometry isn’t particularly complex, the shear mass of building something this large in titanium using the additive process is challenging. Our patented dual, overlapping laser technology contributed to the success of this large titanium part: two lasers working simultaneously on the part in the overlap area enabled not only a faster build, but a larger part as well. Tests carried out on these overlap areas showed there is no difference in quality between the area built exclusively by one laser and the area in the overlap worked on by both lasers interchangeably.

Engineers went through several iterations to prepare the file and build some sample test pieces to see if the job could be accomplished. The customer was trying to achieve a way to manufacture this part that would result in cost and time savings, and weight reduction. This part is noteworthy because of its size and the fact that it was built out of titanium in six and a half days with no process interruptions. The fact that the selective laser melting machine can operate for that period of time without requiring cleaning or experiencing any interruptions is in itself extremely significant.

While 3D printing tends to get attention for its ability to build unique geometries, the nature of this aircraft component was not particularly complex. However, printing a part of this size in titanium in such a short time was something that could not have been achieved had the part been machined out of a billet. With additive manufacturing you’re not restricted to traditional tools and machinery, so you can design in more organic shapes and the entire cycle of designing and engineering a critical part for the aircraft industry is condensed considerably.

“The part’s size meant that it would have taken several weeks to machine conventionally,” explained Richard Grylls, a PhD metallurgist who is the technical director of SLM Solutions NA, Inc. (Novi, MI). “Given that it would have required four or five setups, it would have been a costly process. Casting the part would have taken even longer given that the tooling would have to be built, which could take as long as six months. And traditional tooling is expensive. We were far faster even though the cost was more. Still, in terms of the total time saved, the cost is worth it for a critical part of this size.”

Metal 3D printing excelled in speed and the resulting quality and part density. Meeting the stringent quality requirements and material specifications with titanium in highly regulated industries like aerospace and automotive involves much testing of the materials and optimizing the parameters in order to make sure the customer got what they needed. In general, aerospace/aircraft requirements for inspection are quite extensive, usually involving a CT (computed tomography) scan, a non-destructive test method, to check for porosity or voids in the part, or the customer may perform destructive testing by cutting up the part. Non-destructive testing was used on this part, then a real-world test was performed by mounting it on an engine in its intended use, and running it until it failed.

A recent study funded by the U.S. Department of Energy Advanced Manufacturing Office demonstrated that aircraft weight can be reduced seven percent by replacing conventional means of manufacturing with additive manufacturing – an astonishing number for an industry where most weight efficiency improvements are one or two percentage points.

“Within 20 years, there will be a seismic shift in how we manufacture for the aerospace and defense industry,” said Brian Neff, the managing partner of Neff Capital Management who recently established a new company to focus on the additive manufacturing of production parts for aerospace and defense OEMs around the world. “However, producers who do not understand or are incapable of producing parts with repetitive quality will not play a role in the OEM supply chain.” His newly established company, Sintavia, LLC (Davie, FL), produces parts based on the exacting quality control standards required by the aerospace and defense industry. In addition to a serial production capability, the company maintains a state-of-the-art metallurgical and metrology lab. “We are excited to be a part of the coming industrial revolution within the aerospace and defense industry,” added Neff. “Over the next few years, as more and more production is shifted to additive manufacturing within this industry, serial manufacturers with exceptional quality control will be in high demand by the OEMs.”

Neff Capital funding of Sintavia included a $10 million initial capital investment, rolled out as the company grows and develops its technical capabilities. To support the production of highly complex metal parts, Sintavia added three SLM 280HL selective laser melting systems, one with a single 400 W laser and two with twin lasers of the same power. With a 280 mm x 280 mm x 350 mm build envelope, the SLM 280HL system offers options to configure a single 400 W or 700 W laser, as well as dual (400 W + 1000 W) or twin (400 W or 700 W) lasers. The system uses open software controls, a bi-directional loader and closed-loop metal powder handling to achieve the speed, safety and flexibility needed to optimize strict production parameters.

As the additive manufacturing industry evolves, we are seeing greater demand for more and more applications. We’re being contacted by more traditional manufacturing companies that now need to increase their speed and throughput while maintaining quality. They want to convert conventionally manufactured parts into additive manufacturing. However, the materials and the process of producing these parts are advancing so fast that the standards are quickly becoming outdated. This industry is changing on a day-to-day basis, evolving very quickly, but there is a disconnect between the pace of the evolution in additive manufacturing and the ability of some industries to keep pace with approving new materials and processes, particularly the aerospace and automotive industries.