Cobots Take Center Stage

Collaborative robots are changing the way humans do work and what types of work are considered valuable. Take a look at how they can offer more flexible production, better quality products with fewer resources, a safer working environment, improved employee quality of life – and more profitability.

Posted: December 22, 2016

Collaboration allows the automation of processes that still require humans to be involved, those that cannot be fully automated with existing technology. This opens up entirely new and untapped markets to automation. While conventional robotic systems will still be needed for a long time to come and have several key advantages over current collaborative technology (including higher payloads, much faster cycle times and stronger protection from harsh environments, such as those in foundries), collaborative robots – or cobots – are far less resource-intensive in terms of system design, installation, commissioning and operation when compared to conventional industrial robots. Fully collaborative automation, without safety restrictions and in compact spaces, makes for easier factory installation utilizing existing footprints. Programming in the collaborative environment can also be done by “teaching” the robot, rather than using a coding language.

Collaborative robots elevate the nature of work by allowing people to do jobs that require more thought and are less physically demanding. When humans and robots work together, the process often surpasses the precision and speed of human-only work, resulting in higher quality products and less waste. As people increasingly seek jobs that are more mentally rewarding, collaborative robots make workplaces more appealing and replace the manufacturing skills that are disappearing from the workforce. Freeing up humans from the drudgery of tasks that should be automated is part of a new economy that focuses on harnessing human creativity instead of human productivity. The economy of the future will be full of jobs that are better suited to humans and do not cause the kinds of workplace injuries, both physical and mental, that can exist in our current manufacturing environment.

Collaborative robots are leading a drastic change in the way manufacturing is automated and conducted in the future, a profound shift in the way humans do work and what types of work are considered valuable. The increasing automation of more and more jobs will create an explosion of newer and better jobs that cannot even be envisioned right now. Humans and robots both have their own strengths. When working together, shoulder-to-shoulder in a safe manner, the workplace of the future will be more flexible, produce better quality products with fewer resources, provide a safer working environment, improve employee quality of life, and make manufacturers more competitive.

THE FIRST TRULY COLLABORATIVE DUAL-ARM ROBOT

YuMi® is the world’s first truly collaborative dual-arm industrial robot from ABB Robotics North America (Auburn Hills, MI). This cobot heralds a new era of robotic co-workers that are able to work collaboratively on the same tasks with humans, while still ensuring the safety of those around it. YuMi pushes the boundaries of robotic automation by fundamentally expanding the types of industrial processes that can be automated with robots. Specifically designed to meet the flexible and agile production needs of the consumer electronics industry, this cobot has equal application in any small parts assembly environment thanks to its dual arms, flexible hands, universal parts feeding system, camera-based part location, lead-through programming, and state-of-the-art precise motion control.

Few production arenas are changing as quickly as small parts assembly. The electronics industry in particular has seen demand for products skyrocket past the supply of skilled labor. As conventional assembly methods diminish in value, manufacturers are finding it strategically and economically imperative to invest in new solutions. YuMi can operate in very close collaboration with humans thanks to its inherently safe design. It has a lightweight yet rigid magnesium skeleton covered with a floating plastic casing wrapped in soft padding to absorb impacts. YuMi is also compact, with human dimensions and human movements, which makes its human co-workers feel safe and comfortable. If the cobot senses an unexpected impact, such as a collision with a co-worker, it can pause its motion within milliseconds, and the motion can be restarted again as easily as pressing play on a remote control. YuMi also has no pinch points so that nothing sensitive can be harmed as the axes open and close.

ABB Robotics North America, 1250 Brown Road, Auburn Hills, MI 48326-1507, 248-391-9000, www.abb.com/robotics.

MACHINE TENDING, MATERIAL HANDLING, LIGHT ASSEMBLY

The new Motoman HC10 human-collaborative robot from Yaskawa America, Inc. (Miamisburg, OH) is their first cobot to be introduced outside of Japan. It features a speed- and force-limited design that works safely with or in close proximity to humans. The HC10 ensures the required safety in direct contact with the operator by means of a sophisticated force/torque sensor in every axis that enables flexible interaction between the robot arm and its environment. It has a range of 1.2 m with a handling weight of 10 kg. This cobot is planned to be certified according to technical specification ISO TS15066. It is easy to “teach by demonstration” or simple programming, making it fast to deploy or redeploy on demand. The HC10 is easily adaptable to changing requirements and able to perform a broad range of material handling, machine tending or light assembly tasks.

The HC10 requires no additional protective measures (such as a protective casing), which saves space and expense. Installation is extremely flexible and suitable for a wide range of workstations. Besides its safety aspects, the main focus in the functional design of the new HC10 is on particularly user-friendly operation. Programming can be performed as “easy teaching” with the Smart HUB manual function. Should the cobot be stopped upon contact, it can be reactivated directly on the manipulator. The robot arm is designed to avoid crushing zones. This new cobot is compatible with the controls and hardware of other Motoman models and features all of their benefits: for example, the internal cable routing and wiring ensures a high degree of reliability and low interference contours.

Motoman Robotics Division, Yaskawa America, Inc., 100 Automation Way, Miamisburg, OH 45342, 937-847-6200, Fax: 937-847-6277, www.motoman.com.

POLISHING A MIDNIGHT CHERRY FINISH

When Paradigm Electronics Inc. (Toronto, ON), a manufacturer of high performance loud speakers and subwoofers, launched their “Midnight Cherry” finish on a line of new speakers, the market quickly embraced the new product. “Dealers loved it, our customers loved it, and we were faced with a challenge to make even more of these new cabinets than we anticipated,” explains Oleg Bogdanov, their director of operations who quickly realized that it would take too long to fulfill all demands. “In order to produce that finish you have to apply multiple layers of lacquer, then sand and buff between each layered application. That’s a lot of manual labor. The problem is finding people who can do this. We just couldn’t find enough skilled people.”

The shop already used one robotic cell with a cartesian-type robot. “But the cartesian robot required a lot of protective devices around it for the protection of the worker,” says John Phillips, their senior manager of production services. “It really didn’t allow an employee to work in conjunction with the robot at all. The application of buffing is one that requires a lot of observation and collaboration by the operator, so having the work being done in a remote cell just didn’t seem to be a workable solution.” To meet demand for their labor-intensive products, they implemented a UR10 collaborative robot (cobot) from Universal Robots USA, Inc. (UR; Ann Arbor, MI) in their polishing applications and significantly increased production throughput, eliminating bottlenecks while also improving their work environment.

The UR10 cobot is easy to set up for a new task, with a built-in safety system that enables the robot arm to automatically stop operating if it encounters objects or people in its path. At Paradigm, the UR10 cobot has a built-in, adjustable force mode feature that is easily pre-programmed to handle the most strenuous part of the polishing, using the coarsest buffing compounds. “This cobot has taken over a really delicate job,” explains Phillips. “You make one wrong move with the sand paper and you leave a mark on the cabinet that cannot be repaired. So the robot must be as delicate and as sensitive as a human in properly applying pressure. If too much force is applied, the surface heats and the results go the opposite direction to what you’d hoped. So having the ability for the robot to work to a specific force was a huge advantage. We were aware of technologies that allowed for a force feedback system, but they were actually as expensive as the entire UR10 was to us. So it was quite exciting to find that it has capabilities of force feedback within its inherent structure.”

A human and a robot work in a pendulum type of an operation where they can safely interact, allowing the human to check whether the robot has done an adequate amount of work before the final polishing is handed over to the human. “It’s a very hand-in-hand kind of operation between the two,” explains Phillips, emphasizing the simplicity of the robot cell. Usually there is a long implementation period involving all of the physical guards that are required to make a work cell safe for a human. The cartesian robot the shop uses took five months, but implementation from the time of the receipt of this UR10 cobot was just over a month. It solved their backlog on the popular cabinets by increasing throughput by 50 percent, and the shop estimates their return on investment in the cobot to be about 14 months.

Universal Robots USA, Inc., 5430 Data Court, Suite 300, Ann Arbor, MI 48108, 844-462-6268, ur.na@universal-robots.com, www.universal-robots.com.

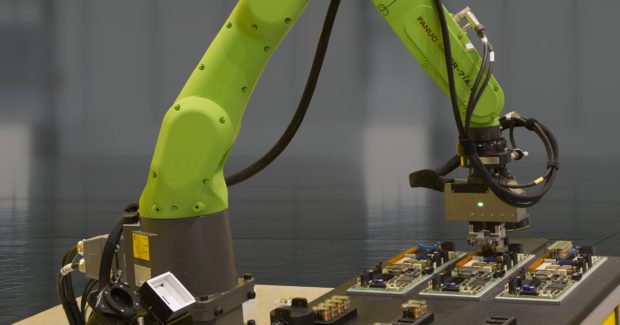

TABLE TOP AND HEAVY PAYLOAD COBOTS

FANUC America Corporation (Rochester Hills, MI) introduced their new CR-4iA and CR-7iA table-top size collaborative robots and demonstrated their CR-35iA heavy payload collaborative robot at IMTS 2016. The CR-7iA, CR-7iA/L, and CR-4iA collaborative robots follow the launch of the larger CR-35iA collaborative robot. “Our collaborative robots are equipped with highly-sensitive contact detection allowing them to share workstations with people,” said Greg Buell, a product manager at FANUC America. “This is a major safety and cost benefit that allows the robot to perform more strenuous tasks or repetitive operations without the need for expensive industrial safety barriers.”

Gearbox Assembly. A new CR-7iA/L collaborative robot mounted to an AGV performed two operations. First, the robot used iRVision to pick planet gears from a rack and used the FS-15iA force control sensor to insert the gears into a gearbox to build three assemblies. The robot then disassembled the gearbox. Next, the robot moved to a second station and picked a relay, presented it to an error-proofing camera to verify that the part is acceptable, then inserted the relay into a circuit board. The robot then disassembled the circuit board and the cycle repeated. The cell featured the new robot’s capabilities to safely interact with an operator, handle different part types, and work on a mobile platform.

Interactive Cell. A new FANUC CR-4iA collaborative robot mounted to a pedestal and equipped with a Rockwell Safety Area Scanner demonstrated the robot’s high-speed mode and contact-stop mode. Visitors experienced the high sensitivity of the robot’s contact stop and push-to-escape features. In addition, the cell showcased the CR-4iA’s tap-to-resume feature.

Motor Assembly. A FANUC CR-35iA collaborative robot equipped with iRvision picked an unfinished motor from a pallet and placed it at a work station where an operator attached several parts on the motor’s shaft as the robot retrieved a second motor. The robot placed the second motor on the work station, then picked and rotated the completed motor, allowing the operator to attach an inspection tag. The robot then transferred the completed motor to a finished motor pallet. After three assemblies were completed, the operation was done in reverse. This cell featured very close human/robot collaboration in an interactive application.

“The CR-35iA collaborative robot allows shared workspace between an operator and the interactive robot,” added Buell. “The highly-sensitive robot gently stops if it comes in contact with the operator, allowing the robot and human to work side by side.”

The CR-7iA offers a 717 mm reach and 7kg payload; the CR-7iA/L offers the same payload with a longer 911 mm reach; and the CR-4iA has a 550 mm reach and 4 kg payload. The design for the new compact collaborative robot series is based on the widely popular LR Mate-series of mini material handling robots. These new robots are ideal for small part sorting and assembly, inspection, machine tending and part delivery. All of FANUC’s collaborative robots are green to distinguish them from their standard yellow robots. The new CR-7iA, CR-7iA/L, and CR-4iA collaborative robots provides a wide range of features and benefits, including:

- Three compact variants offering 550 mm to 911 mm reach and 4 kg to 7 kg payload capabilities.

- Floor, wall and ceiling mounting options.

- Safety-rated contact detection and familiar green exterior color.

- Designed with the same high reliability as FANUC conventional robots.

- Works in cooperation with a human operator in a variety of manufacturing applications.

- Supports the latest intelligent functions, such as iRVision and Force Sensing.

- Designed to meet the safety requirements of ISO 10218-1:2011 and RIA/ANSI R15.06-2012.

- Operates with the small R-30iB Mate controller, capable of running on 120 V.

The CR-35iA collaborative robot features six-axis articulation. A soft green cover protects workers who are in direct contact with the robot, which was developed to help manufacturers solve ergonomic challenges by handling applications that are physically demanding for humans, such as heavy lifting. In the automotive industry, for example, workers are required to lift spare tires into vehicles on the assembly line. “The CR-35iA can work alongside the employees assigned to this task to help reduce injuries associated with repetitive or heavy lifting,” noted Buell.

Certified to meet the requirements of ISO 10218-1:2011 and RIA/ANSI R15.06-2012, the CR-35iA collaborative robot can work in a variety of applications alongside human workers including: machine tending, handling heavy payloads that require lift assist devices or custom equipment, higher payload mechanical assembly, palletizing or packing, and tote or carton handling. This robot offers a wide range of collaborative and safety features and benefits, including:

- Industry’s first 35 kg payload collaborative robot that can work with humans in a shared workspace without safety fences.

- Works in cooperation with a human operator in a variety of applications including assembly and heavy-duty part transfer.

- Stops safely when it touches a human operator.

- Soft green cover minimizes impact force and prevents human operators from being pinched.

- Certified to meet the requirements of international standards ISO 10218-1.

- Supports the latest intelligent functions such as i

- Designed with the same high reliability as FANUC conventional robots.

FANUC America Corporation, 3900 West Hamlin Road, Rochester Hills, MI 48309, (888-326-8287, www.fanucamerica.com.