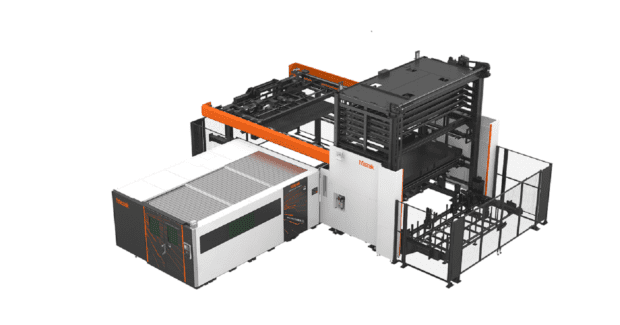

Compact, High Speed Laser Cutting Automation

Ideal for unmanned operations, the compact QUICK CELL 3015 automated laser cutting system from Mazak Optonics uses factory floor space more efficiently by stacking the load and unload pallets.

Posted: December 20, 2016

Mazak Optonics Corporation (Elgin, IL) introduces the compact QUICK CELL 3015 automated laser cutting system which performs unmanned operation while having a small footprint for facilities with limited floor space. By having the load and unload pallets stacked, this system allows factory floor space to be used more efficiently. The load and unload units each have a separate drive system, instead of being combined, which results in high speed operation time under 60 seconds for materials 12 mm and thinner, which is much faster than conventional systems. The QUICK CELL 3015 has one-inch thick capacity and offers the flexibility to meet a shop’s production requirements. The stocker can be expanded to 6 levels, 10 levels, or 14 levels after installing the standard base system. The number of pallets used for material and the number of pallets used for finished parts can be freely selected for the 6 level, 10 level, and 14 level stockers.

Mazak Optonics Corporation, 2725 Galvin Court, Elgin, IL 60124, 847-252-4500, sales@mazaklaser.com, www.mazakoptonics.com.