Connected Machining

As manufacturing moves toward Smart Factories that optimize manufacturing processes, great advances in machine connectivity are adding value to automation, production data management and machine intelligence like never before.

Posted: December 29, 2016

One of the many important trends being discussed in manufacturing today is the importance of machine connectivity and how the great advances being made in this area are adding value to automation, production data management and machine intelligence like never before. Connected machining begins with an examination of digital job management in the manufacturing process.

It is important to note that, especially in the case of automated production of small series or even individual parts, a powerful and flexible control is required. Such a control system must have the necessary intelligence in order to implement the machining requirements while observing the required tolerances. These include, for example, a powerful motion control system, a comprehensive set of probing cycles for checking tolerances, and, if necessary, adding offsets to cutting tools. In addition, such a control must have the functionality to protect cutting tools from possible overloading and, if necessary, to use a replacement tool in time or even to protect the machine from a collision in the event of a program error.

Complex machining centers are often operated in combination with other systems, such as a pallet station or other control systems. This means the exchange of data with other systems is unavoidable and also the easy access to data by the operator is an important advantage. Last but not least, when optimizing processes, it is important to record the machine data over a longer period of time in order to be able to reliably assess the processes and to identify possible savings potentials. All of these elements of digital job management should be considered when selecting the control for machine connectivity.

https://youtu.be/kMCiKYqKFqk

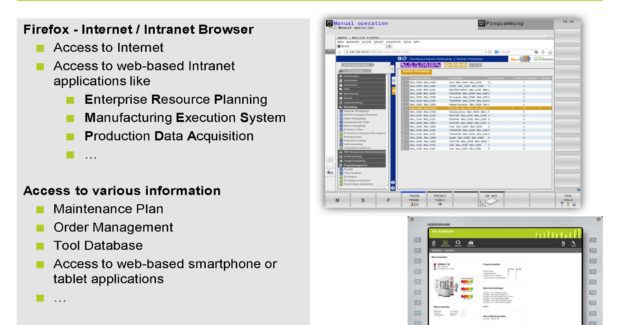

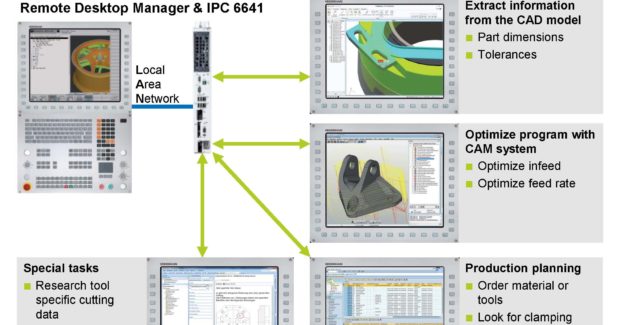

For example, the standard (not optional) browser for connectivity that is included in our TNC control is mainly useful for accessing web-based intranet applications. Access to the Internet is possible, but not the sole purpose of the browser. Instead, more and more application programs offer a web interface for operation that can be linked from the TNC control via the browser. If an application does not have a web interface, the TNC’s Remote Desktop offers the possibility to connect one or several computers which can have different operating systems, and to control the application available on the computers from the control. Possible applications include running an operating system on an industrial PC (or IPC) that is connected via remote desktop. Any applications shown in Figure 1 and Figure 2 can then be operated through the control.

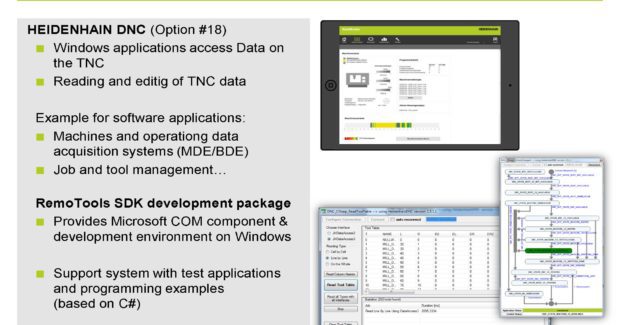

Using our DNC (distributed numerical control) interface to the control, Windows applications can access TNC controllers via the Microsoft COM component and read and modify data, and load NC programs. In addition there is also the possibility to create numerous events, and status changes can be automatically captured and recorded. A unique development package called RemoTools SDK can be used indefinitely by the user for creating their own applications. This package includes the Microsoft COM component, the associated documentation, and examples with the corresponding code C # for tests and programming trials for various functions (see Figure 3).

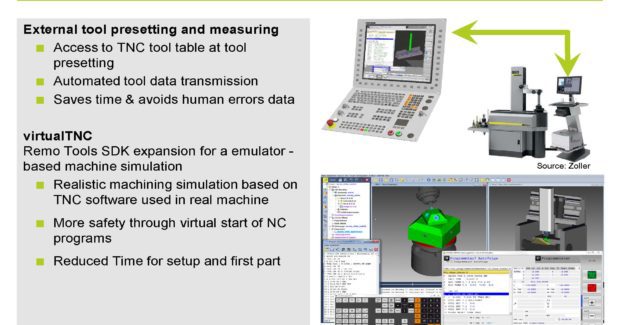

An application example for Remotools SDK is shown in Figure 4. The data of the cutting tool are automatically transferred to the tool table of the TNC controller after the measurement on an external presetter. VirtualTNC is a software extension to RemoTools SDK that is activated via a dongle (a small hardware device that connects to another device to provide it with additional functionality) that we can provide. When an NC program is loaded and run via the programming station, the actual position values determined by the controller can be read out and a third-party simulation tool (such as programming verification software) can be operated based on these position values. This means the simulation is based on the actual position values of the controller. The processing can also be accelerated via a boost function up to the maximum of the calculation speed possible by the respective processor. In order to get 1:1 simulation of all functions and cycles of the TNC, a preparation of the programming station is required to have the same datum tables and kinematics, for example.

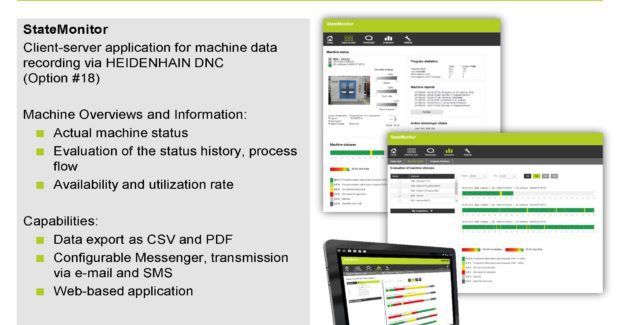

StateMonitor is a solution for recording machine data based on our DNC interface that only records data / status changes and does not make any changes to the data of the connected TNC controllers (see Figure 5). Based on the acquired data, evaluations can be carried out within StateMonitor or exported to other systems. This allows real plant utilization and availability to be recorded comfortably and provides the basis for the targeted optimization of machining processes. The Messenger that is integrated inside StateMonitor offers the possibility to send notifications via e-mail or SMS based on freely configurable events. Depending on the fault or machine message, the respective contact person can be informed quickly and comfortably. Reaction times, especially in the case of unmanned shifts, can be shortened significantly in this way.

While all of these tools are essential for the flexibility of today’s CNCs, control manufacturers also need to prepare for future trends in connected machining. The industry will likely see a process toward standardization of protocols such as already happened with formats such as MTConnect and OPC UA. But the challenge will also be to guarantee the security of data within manufacturing firms, especially if those firms decide to share the data with third parties. Naturally, the tools available today and those that are to be developed for the “Smart Factories” of tomorrow must all serve the goal of optimizing manufacturing processes.