Virtual Reality Unites Manufacturing Teams

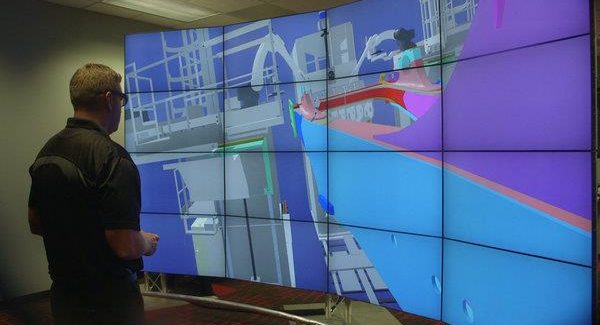

Genesis uses 3DG technology from Mechdyne to make technical recommendations, applications direction and programming requirements during virtual reviews with customers before they build a robotic automation system.

Posted: December 22, 2016

Immersive visualization in the manufacturing world has proven its value time and time again during design reviews, proof-of-concept validation, and customer engagement. Organizations are experiencing faster buying cycles, accelerated time-to-market, and minimized risk as they optimize designs in the virtual space. Over a year ago, Genesis Systems Group, LLC (Davenport, IA) started seeing these benefits firsthand in their digital proof-of-concept processes for robotic automation systems. However, their 3D technology also began providing benefits they weren’t expecting: a more cohesive team and better collaboration. “We are using the technology more for internal design reviews than we anticipated, which is creating a lot more opportunity for our teams to work together,” explains Justan Each, the virtual solutions manager at Genesis. “Because more people are reviewing designs in the virtual world before we build one of our robotic systems, we are seeing fewer design errors and more optimized solutions.”

In March 2015, Genesis first partnered with Mechdyne Corporation (Marshalltown, IA) to design and integrate an audiovisual and information technology (AV/IT) solution to virtually review and change concepts and designs. The solution, called the 3DG, consists of a curved, four-by-four tiled technology system with mobile capabilities. Finalizing a virtual design requires a versatile, agile approach to optimize a solution. Historically, engineers and product designers create and adjust a concept design with the client, then generate a more detailed model before production would began. Now, Genesis engineers are able to make design recommendations and plan for production more easily: their technicians make recommendations with cable runs, applications engineers have a better direction to begin programming requirements, and sales is more comfortable with engineers and designers directing conversations with clients during design reviews.

“Our goal is to have minimal design changes from concept to fabrication,” notes Each. “Because our teams are working together more closely, we are seeing that goal come to life.” When prospective or current clients visit the Genesis headquarters, they invariably end up in their Virtual Solutions Center to become introduced to the process or review robotic designs. Sales engineers that were once hesitant with the technology now turn over control to the engineers and designers to begin discussing solution design, creating a comfortable, collaborative, and customized atmosphere. Experiencing one of these robotic solutions in the virtual world leaves customers feeling engaged and excited to move forward with a purchase, seen most evidently as Genesis recently hit their record for closing-sale day in partial thanks to the 3DG.

“We had two large sales in one day and it is tied back to seeing the designs in the 3DG, knowing exactly how the solutions were going to work, and what our process would be,” says Andrea Petersen, the communications manager at Genesis. “Our sales process was cut by two months. We walked away with a record sales day and two robotic automation programs totaling over $10 million. That’s credited to the improved way we work together.”

Genesis Systems Group, LLC, 900 North Harrison Street, Davenport, IA 52806, 563-445-5600, www.genesis-systems.com.

Mechdyne Corporation, 11 East Church Street # 400, Marshalltown, IA 50158, 641-754-4649, www.mechdyne.com.