Advanced Tube Fabrication Systems

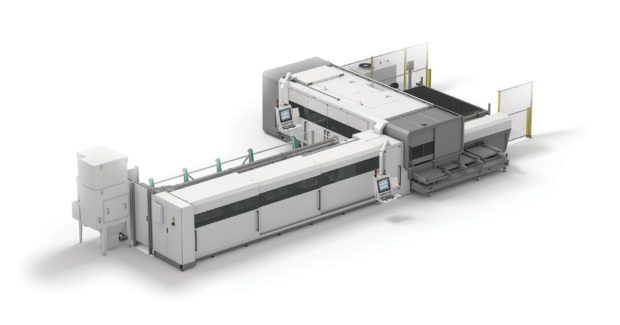

The LC5 tube and sheet fabricating machine, the LT-FREE fiber laser tube cutting machine for cutting 3-dimensional parts, and the E-TURN and 4-RUNNER tube bending machines from BLM are ideal for effective, automated high volume fabrication of difficult materials.

Posted: January 28, 2017

BLM Group USA (Wixom, MI) offers the LC5 tube and sheet fabricating machine, the LT-FREE fiber laser tube cutting machine for cutting 3-dimensional parts, as well as the E-TURN and 4-RUNNER tube bending machines. The LC5 is a compact laser machine that can be equipped with either a CO2 laser source with a power up to 4.5 kW, or a fiber laser source with a power up to 5 kW. It is the only high production machine with automatic loading and unloading that can process both tube and flat sheet in a single machine. The LC5 can handle tube up to 334 in long and 4.75 in diameter. The processing of sheet metal is fully automatic and allows for sheet up to 78 in x 236 in. The fiber laser is ideal for cutting both mild steel and highly reflective materials such as stainless steel and aluminum.

The LT FREE is a five-axis, fiber laser system designed for cutting three-dimensional formed or shaped parts, such as bent tubes, hydroformed tubes, welded assemblies and stamped or flat sheets. With powers up to 3 kW, table dimensions of 59 in x 39 in, and axis stroke to X 116 in, Y 37 in, and Z 29 in, it is ideal for cutting mild steel, copper, aluminum, brass, stainless steel and galvanized steel. The E-TURN 32 tube bender can handle tube up to 1.18 in diameter and can be equipped with a Kawasaki robotic arm. This all-electric tube bender can bend a variety of tube configurations, including round, square, rectangular, flat-sided, oval and elliptical. Tube can be automatically loaded, bent and unloaded all in one machine.

The 4-RUNNER tube bender and end-forming machine can be configured as a dedicated tube bender for a specific production application or a complete process that includes straightening from coil, bending, end-forming and cut off. With a footprint of 13.08 ft x 7.17 ft x 6.17 ft, the 4-RUNNER is ideal for machining small to medium sized tubes and can bend tube to 0.875 in diameter with accuracy to ±0.05 in on the linear axis and ±0.05 deg on the rotational axis. The unit comes standard with 2.76 in maximum bending radius, and an increase bend radius option is available.

BLM also offers the BC80 end-machining center and CM602 automatic sawing machine. The BC80 is a highly productive and completely automated CNC end-machining center ideal for cut-to-length, chamfering, facing and part measurement for round-the-clock production of bushings up to 3.15 in diameter and lengths from 0.4 in to 13.75 in. The bundle loader is available in lengths up to an astounding 40 ft, and the unit provides in-process part measurement and 100 percent part length inspection with detailed SPC reporting. The CM602 automatic CNC sawing machine is ideal for cutting short and medium length steel, copper, brass and aluminum tubes, solid bars and profiles. The cutting head is positioned at 45 deg to the tube surface and its linear movement across the tube provides a uniform load on the blade resulting in less noise, less scrap and longer blade life. The CM602 can handle tube and bar up to 4 in diameter depending on material, and runs at up to 5,000 rpm cutting speed.

BLM Group USA, 29380 Beck Road, Wixom, MI 48393, 248-560-0080, sales@blmgroupusa.com, www.blmgroup.com.