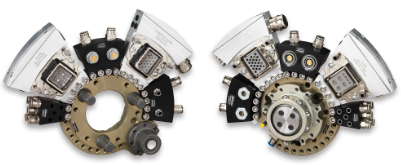

Robotic Tool Change System

Ideal for medium payload range automotive applications, the compact MPS 130 fully automatic tool change system from Stäubli is only 1.8 kg on the robot side and 1.1 kg on the tool side, with a maximum load of 100 kg and a bending moment of 900 Nm.

Posted: January 3, 2017

Stäubli Corporation (Duncan, SC) introduces their new compact MPS 130 fully automatic tool change system for medium payload range. The MPS 130 is ideal for applications in the automotive industry, but the advantages of this automatic gripper and tool changer should open up other robot applications as well. Particular attention has been paid to the weight-optimized tool changer so that users do not have to invest in robots of the next highest payload category. The weight of the MPS 130 is only 1.8 kg on the robot side and just 1.1 kg on the tool side. It has a maximum load of 100 kg and a bending moment of 900 Nm. As with larger models, this new addition meets the strictest safety requirements according to safety category 3, performance level d.

The tool changer can be equipped with customized modules and components for media, data and electrical power transmission. To guarantee maximum reliability, Stäubli is the only manufacturer worldwide to develop and produce the complete changer single-handedly. The locking mechanism, the media module and the entire connection technology comes from a single source. The advantage is that all components are produced under an integrated quality management system in the highest production quality.

Stäubli Corporation, 201 Parkway West, Duncan, SC 29334, 864 486-5430, j.abel@staubli.com, www.staubli.us.