Advanced Machining and Measurement Systems

P.D. Browne provides advanced machine tools from Murata Machinery, You Ji, Johnford and Sodick, and innovative CMMs from Aberlink.

Posted: February 1, 2017

In Booth 2521, P.D. Browne South Machine Tools (Houston, TX) has served manufacturers in Southern Texas for the past 30 years with the most productive and technically advanced CNC machine tools on the market, providing comprehensive service, training, and applications support. As a distributor for Murata Machinery USA, Inc. (Charlotte, NC), they will showcase the twin spindle Muratec MW200G CNC turning center for mid- to-high volume production parts. With single or fully independent twin gantry robot options, this machine meets production requirements for high production needs. Built to run around the clock, the MW200G is used extensively in the automotive industry for mid-to-high production turning of transmission and steering applications requiring the ultimate in precision, control, and repeatability

With dual simultaneous operations on the spindles, cycle time is maximized. Compared with traditional single-spindle machines, the compact design for line planning saves space in production setup. An intelligent three-axis CNC gantry robot loader allows quick work loading/unloading at stocker systems, conveyors, post-process gauges and post-process systems. “With two 10-station turrets, this high speed automated machine delivers the ultimate throughput and flexibility,” explained Steve Landrum, the North American sales manager of the Turning business unit of Murata Machinery USA.

P.D. Browne will also present the You Ji AH-06 CNC Turning Center that is specifically designed as a direct replacement for popular heavy duty CNC turning centers manufactured in the 1980s. While current production CNC turning centers may lack the power and rigidity of older large machines, the AH series delivers special performance that often can’t be found on other modern turning centers. Its one-piece 45 deg slant bed casting is massive. Even the shortest bed length weighs in at nearly 40,000 lb. Bed lengths start at 40 in and go up to 160 in. To both enhance operator accessibility and add mass to the saddle assembly, the cross slide is at 55 deg angle. Widely spaced box ways in both axes, with hand scraped Turcite-B applied to mating surfaces, provide superior cutting performance and precise positioning. Large diameter precision ballscrews (2.5 in Z-axis) and high power Fanuc servo motors deliver high axis thrust for heavy turning, boring and drilling.

The heart of any lathe is the spindle, and You Ji’s spindle is everything users need in a heavy duty machine. Using two sets of double row roller bearings for radial loads and a pair of angular contact bearing for axis loads, this proven design delivers unsurpassed strength and precision. The spindle is housed in all-geared headstock. The three-speed geared head is equipped with an oil chiller unit to maintain thermal stability. A 60 hp Fanuc motor driving the spindle through the three-speed gearbox provides exemplary torque of 3,154 ft-lb at just 100 rpm. To take all of that power, the massive 12-station hydraulically actuated and clamped turret delivers. The 6.5 in thick turret tool disk houses 1.25 in square shank turning tools and boring bars up to 3 in.

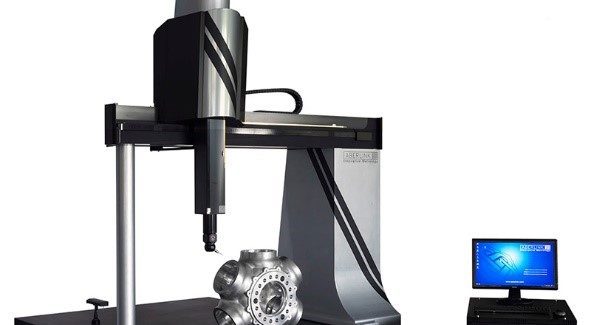

Also on display will be the innovative Extreme shop floor CMM and large Azimuth CMM from Aberlink Ltd. (Eastcombe, UK). The new Extreme is a self-contained shop floor machine with a 300 mm x 300 mm x 200 mm measuring range and unique built-in temperature control, easy to use software, built-in monitor and keyboard that truly brings a full CNC CMM to the small shop that can be placed almost anywhere at half the price of most small CMMs. The Aberlink Axiom, Zenith and Azimuth models all provide the same type of cost savings, with machine sizes up to the Azimuth 1,200 mm x 3,000 mm x 1,000 mm and accuracies down to 1.8+L/250. Design options include the incorporation of items such as the Revolutionary Renishaw PH20 5-axis touch probe system for large volume production environments where inspection times can be reduced by as much as 80 percent.

https://youtu.be/cC86nZYRwKs

These CMMs include lifetime software updates for Aberlink 3D measurement software that eliminates the need for expensive yearly software contracts provided by other CMM manufacturers. Standard onsite training and a video training course make it easy to become proficient in the use of the software and equipment. A video camera option further enhances the flexibility of the CMM. A coolant tank is separated from the machine base to prevent heat transfer from the coolant to the machine casting, help ensure precision, and promote easy cleaning and maintenance. Standard features include an extra wide high-capacity chip conveyor, programmable tailstock, oil skimmer, and the fully loaded Fanuc OiT-F control with 10.4 in LCD and Manual Guide i conversational programming.

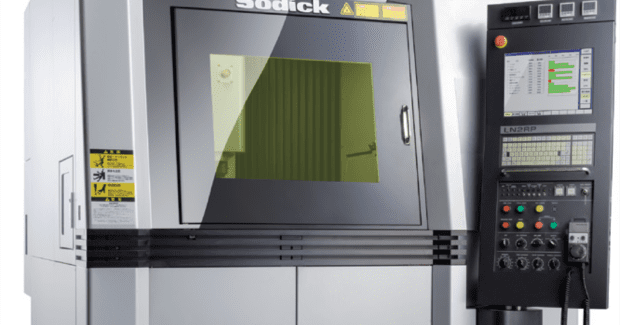

P.D. Browne will also display the VL600Q advanced performance wire EDM from Sodick Inc. (Schaumburg, IL) that features 23.6 in x 15.75 in XY travels. It makes use of the premium “Pop-Up” AWT function that allows for fast, automatic rethreading. This feature improves threading performance on even the most difficult surfaces, such as sloped or hollow forms. The VL model offers additional upgrades over the previous-generation VZ model, including an advanced surface finish circuit that achieves both faster and finer finishes. Also on display will be the Sodick AD55L sinker EDM with a 47.25 in x 31.5 in worktank, zero-electrode-wear capabilities, and arc-less machining circuit. With cutting performance equivalent to a premium AG series sinker, the AD series offers high-speed, high-accuracy EDM capabilities in a manual-door configuration. For attendees in need of superior cutting performance without the extra frills of an automatic drop tank, the Sodick AD series serves as a workhorse machine with minimal maintenance requirements.

P.D. Browne South will also offer a glimpse into the Sodick OPM250L Metal 3D Printer that is capable of both printing and milling metal components in a single powder-bed process to produce highly specialized designs that are impossible to produce in any other way, such as conformal cooling channels within molds or finished surfaces within enclosed structures. The OPM250L can quickly print a variety of high-hardness tool steels with a 99.99 percent density – the highest melt ratio on the market. This system is backed by over 12 years of experience with additive technology that was developed by Sodick’s own OPM Laboratory founded in 2003.

P.D. Browne will also present the heavy duty, high precision Johnford ST-80GX CNC turning center cast from Meehanite iron. Full advantage of the 50 hp spindle motor and four-speed gear box is taken by the massive one-piece 60 deg slant bed design. Built in classic style, the 60 deg slant bed features a torque tube design. The torque tube, or hole, cast through the center of the slant bed provides an extremely rigid bed and excellent heat dissipation. The square box ways provide the rigidity for heavy duty turning. Hand scraped Turcite-B applied to all mating sliding surfaces ensures high rapid traverse rates and accurate positioning. Offering precision and thermal stability, the headstock, tailstock, and saddle are all mounted on the same plane at a 60 deg angle.

The coolant tank is separate from the machine base to prevent heat transfer from the coolant to the machine casting which promotes precision and easy cleaning and maintenance. To further enhance accuracy and precision, the ballscrews are the double-nut type and pre-tensioned to eliminate thermal growth. The precision spindle structure with the extra-large hole uses Timken roller bearings for rigidity and accuracy. The spindle quill inner and outer linings are precision ground for fit with the spindle, providing extreme concentricity and accuracy. The spindle is driven by a 50 hp high torque motor that provides plenty of power to the A2-20 spindle. For applications requiring high torque at low rpm, a four-speed gear box is standard. A 60 hp spindle motor is also available for high power cutting.

A 12-station bi-directional turret or optional BMT servo live turret provides 0.5 second indexing and coolant through the tool holders. A full C-axis with live tools is available for applications requiring milling operations. Fanuc controls are standard for performance and reliability.

P.D. Browne South Machine Tools, 440 Benmar #3150, Houston TX 77060, 281-405-9378, Fax: 281-405-9382, gerald@pdbrowne.com, www.pdbrowne.com.