Advanced Monitoring of Machining and Tooling Operations

Excellent for unattended operation, advanced systems from Caron Engineering monitor tool wear and breakage with immediate machine stop and retract if a tool breaks to minimize damage, and adaptive controls to monitor true power and automatically adjust the feed rate.

Posted: February 2, 2017

In Booth 2112, Caron Engineering, Inc. (Wells, ME), together with their new Texas integrator Wolfram Manufacturing (Austin, TX), will showcase a custom kiosk running demonstrations of their unique line of products that enhance the abilities of CNC machines to improve performance, productivity, and profitability. TMAC (Tool Monitoring Adaptive Control) monitors tool wear and breakage with immediate machine stop and retract when a tool breaks to minimize damage. TMAC is excellent for unattended operation. Its adaptive control option monitors true power and automatically adjusts the feed rate to maintain a constant tool load. It can also monitor vibration, strain, coolant pressure, coolant flow and spindle speed, with the added capability of monitoring spindle bearing health with a new bearing analysis feature.

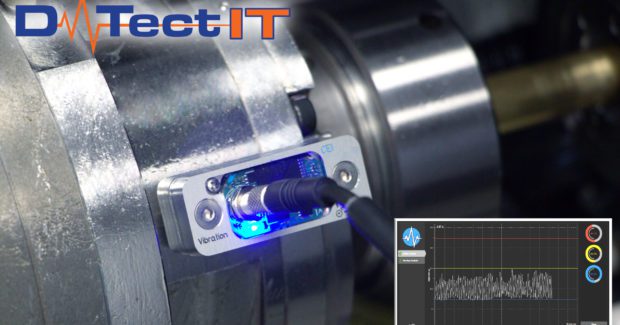

DTect-IT is capable of detecting vibration irregularities anywhere on a CNC machine tool or fixture. It can also monitor small amounts of force, or anything with a 0-10 VDC signal through connection of an analog sensor. The latest features for DTect-IT include a built-in audio sensor that records from any audio device on the DTect-IT windows PC. DTect-IT can also collect raw data from any DTect-IT sensor, up to 62,500 data points per second. The kiosk will also have AutoComp software that processes gauge data from any electronic gauging device and automatically adjusts tool offsets to the CNC control. AutoComp statistically controls tool offsets to maintain acceptable tolerances of the machined parts by calculating tool compensation based on set tolerance limits and tool compensation limits. AutoComp virtually eliminates operator data-entry errors for error-free tooling control.

Tool Connect is a tool identification system for machine tools using RFID. It automates the transfer of tool presetter data from RFID tags (embedded) in tool holders to the CNC control. It is customizable to display any user-defined information. The tool presetter measures the tool and writes data to the RFID tag. The tool is placed in a custom chip reader at the machine and data is automatically written to the control. Tool Connect tracks tools when removed and updates tool life info to the RFID tag. Lastly, the kiosk will be equipped with a CEI Smart Light system that provides easy assessment of a part’s progress on a CNC machine. This intuitive status light system can be configured to show any machine status or condition. At a glance, an operator can see what the machines are doing, without having to continually check each control.

https://youtu.be/Ki_6nPdr7wg

Caron Engineering, Inc., 1931 Sanford Road, Wells, ME 04090, 207-646-6071, marketing@caroneng.com, www.caroneng.com.