Continuous Innovation for Large Format Demands

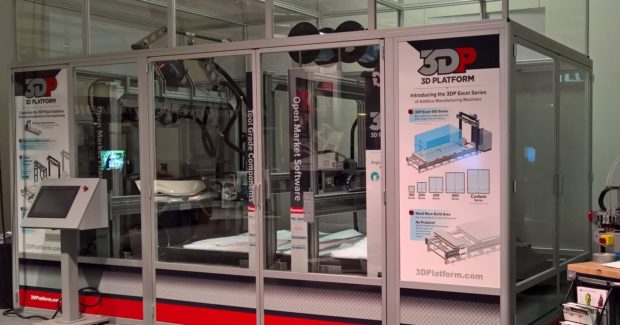

Large-format Excel Series 3D printing machines from 3D Platform offer a parallel gantry configuration that can scale to growing application requirements and support simultaneous additive, subtractive, and robotics processes.

Posted: February 20, 2017

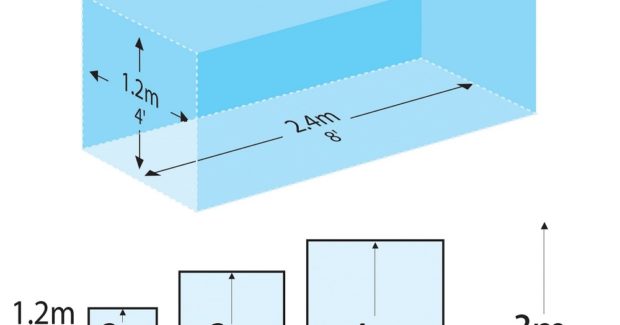

As metal fabricators race toward affordable, large-format 3D printing that can scale to growing application requirements, 3D Platform (3DP; Roscoe, IL) continues to shape the future of 3D printing with their Excel Series Platform that introduces a parallel gantry configuration that can support multiple simultaneous processes, including additive, subtractive, and robotics. Breaking through barriers of size and throughput, the Excel 100 Series starts with a 4 ft x 4 ft x 8 ft (1.2 m x 1.2 m x 2.4 m) build area with an array of high volume extruder systems that realize a material throughput capacity from 2 kg/hr to as high as 55 kg/hr per gantry. This is possible by leveraging the power of multiprocessing, parallel gantries and a combination of additive, subtractive, and robotic configurations. The build area can be extended to virtually any length needed (100 m +) to offer large formats like never before.

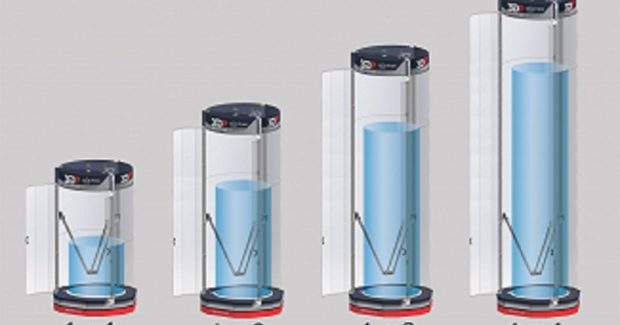

The XL-Delta and the Excel-Multi Gantry large format printers provide custom work areas from 0.5 cu m to +3 cu m. These extended work areas allow machine operators to 3D print on scales that reach nearly 2.5 m across and 2 m tall, with nozzle sizes up to +4.5 mm. These machines increase the throughput of the materials while decreasing the 3D print time for each project. The power of multiprocessing using parallel gantries and a combination of additive, subtractive, and robotic configurations that push previous application limits by providing the potential material throughput to 1.5 kg/hr to 2 kg/hr.

Closing the door on proprietary solutions, 3D Platform approaches these new printer concepts with open market platforms that leverage material science developments and best-in-class partnerships to expand served applications. The Excel line brings together an all-star partnership with PBC Linear, Xtrution, THK, Yaskawa, and Shimpo contributing to the solid industrial design built into this machine. These partnerships shape linear guides and multiple gantry systems, while powering motion control and industrial robotics technology.

The 3DP line of additive manufacturing machines offers affordable solutions to users who seek higher speed to market and manufacturing agility, and know that 3D printing machines hold the future to those goals. While competitors struggle for acceptance of higher priced offerings, these systems continually answer demands for reductions in machine and operating costs. A key holdup in widespread adoption of 3D printing technology has been cost of ownership and operation. Studies of printing common industrial parts have shown that these machines can reduce operating costs up to 10X in materials used, as well as a 10X reduction in machine acquisition costs when compared to other systems.

3D Platform, 6402 Rockton Road, Roscoe, IL 61073, 779-771-0000, 3DPlatform.com.