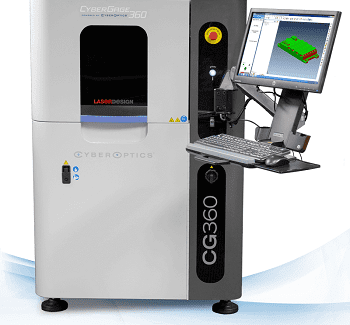

One-Button Automated Scanning of Complex Parts

By allowing anyone to be an inspector of in-process and incoming/outgoing parts on the shop floor, the CyberGage360 from Laser Design is ideal for applications where high accuracy and high speed throughput are vital, including consumer electronics, medical, automotive, aerospace and more.

Posted: February 27, 2017

Laser Design, Inc. (Minneapolis, MN) offers the metrology-grade, ultra-precise and ultra-fast CyberGage360™, a one-button automated 3D scanning and inspection system that greatly facilitates quality assurance by allowing anyone to be an inspector of in-process and incoming/outgoing parts on the manufacturing floor, lowering the cost of quality and speeding products to market. With little training, anyone can check parts for any deviation from CAD or check critical features. Designed for use in general purpose metrology, the CyberGage360 has a range of potential applications for consumer electronics, medical, automotive, aerospace and other verticals, where high accuracy and high speed throughput are vital. With one-button simplicity, a highly precise 360 deg scan of complex parts can be generated in less than three minutes.

https://youtu.be/8dvYmiG7PTs

Incorporating proprietary 3D Multi-Reflection Suppression (MRS) technology, the automated CyberGage360 brings significantly greater accuracy and scanning speeds to the industrial parts inspection and reverse engineering markets. “3D scanning of complex parts now simply involves opening a door, putting your part in, and pressing a button” said C. Martin Schuster, the president and chief executive officer of Laser Design. “The result is a highly precise 3D scan with a full 3D inspection report in a matter of two to three minutes. We have integrated our proprietary 3D MRS scanning technology for an unprecedented combination of speed, accuracy and simplicity that has yet to be seen in the industrial 3D scanning markets.” In addition to a series of systems, the company also offers 3D Services that include 3D laser scanning services for reverse engineering, quality inspection and to capture internal and external geometry.

Laser Design, Inc., 9401 James Avenue South #132, Minneapolis, MN 55431, 952-884-9648, www.laserdesign.com.