Producing High Hardness Tool Steels on a Hybrid Machine

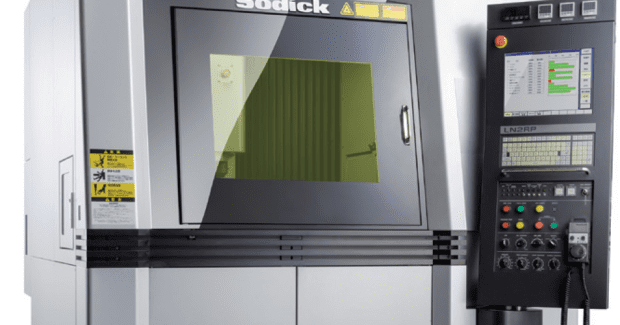

The OPM250L Metal 3D Printer from Sodick can quickly print and mill a variety of high hardness tool steels with a 99.99 percent density.

Posted: February 24, 2017

The OPM250L Metal 3D Printer from Sodick Inc. (Schaumburg, IL) is capable of both printing and milling metal components in a single powder-bed process to produce highly specialized designs that are impossible to produce in any other way, such as conformal cooling channels within molds or finished surfaces within enclosed structures. The OPM250L can quickly print a variety of high hardness tool steels with a 99.99 percent density – the highest melt ratio on the market. This system is backed by over 12 years of experience with additive technology that was developed by Sodick’s own OPM Laboratory founded in 2003.

Sodick Inc., 1605 North Penny Lane, Schaumburg, IL 60173, 847-310-9000, Fax: 847-310-9011, www.sodick.com.