Raising the Bar in Yacht Racing

Metal 3D printing technology increases yacht racing performance through advanced rapid prototyping capabilities that allow this British yacht racing team to refine custom parts on demand and reduce their costs.

Posted: February 17, 2017

Land Rover Ben Ainsile Racing Ltd. (BAR; Portsmouth, England) is no stranger to cutting edge technologies. This British yacht racing team, formed by four-time Olympic gold medalist and America’s Cup winner Sir Ben Ainsile, uses artificial intelligence, big data analytics, and most recently, additive manufacturing (3D printing) to gain competitive advantages. These technologies have been incorporated into daily use at Land Rover BAR by the team’s Technical Innovation Group (TIG) through a partnership with Renishaw plc (Wotton-under-Edge, England), a global metrology company that also manufactures metal additive manufacturing machines. Their partnership has allowed the team’s engineers to design and test precision custom parts quickly and cost effectively in the shop, and give them an edge on the water.

“We use 3D printing at three different levels within our team,” explained TIG project manager George Sykes of PA Consulting Group (London, England). “The simplest level is as a prototyping and visualization tool. We manufacture a large number of custom parts and 3D printing allows us to make full size prototypes in-house before we commit to a design.” The team has their own fully equipped traditional machine shop, as well as an extensive additive shop facility. Between them, these facilities can make almost anything, but if the final part can be 3D printed then that is the option used, because typically the cost can be significantly reduced. “The prototyping process is really useful when we are trying to develop a new idea,” noted Andy Claughton, the chief technology officer of Land Rover BAR. “It allows us to get our hands on it, put it in place on the boat or link it up with other parts of the system to see potential issues and refine the design before we commit to the production of the final piece.”

“One example is the end cap for the boat’s bowsprit,” added Sykes. “This is a complex shape, designed to reduce the aerodynamic drag. It was ideal for 3D printing because there was no load involved, and a single item was required. In years gone by this would have been built in carbon fiber to the finish specs and standards of a piece of custom furniture – and at great expense – due to the time and skill of those involved. Now, once the design has been developed it can be produced in a handful of hours at a much lower cost.” Now the team is taking additive manufacturing even further. “The top level of our 3D printing program is the metal additive manufacturing supplied by Renishaw,” continued Sykes. “The manufacture of custom parts in metal is the cutting edge of this technology.”

The components are manufactured from paper thin layers (typically 0.05 mm) of fine metallic powder with the consistency of cornflower. The system works inside an argon inert atmosphere that is similar to that inside a light bulb. Heat can be applied to melt the metal powder without it burning or reacting with oxygen or impurities found in air. The heat is applied using a laser beam that is directed by using software-controlled mirrors and focused to accurately weld the areas required to create the part. One of the earliest components that the team created using this technology was a custom sheave case for the pulley in the daggerboard lift line. “There was a high compressive load involved and it needed good resistance to wear, so metal was the ideal choice,” recalls Sykes. “All of the high strength metals have a higher density (weight per volume) than carbon fiber, so to keep weight down the final design was hollow. It would have been very difficult to make this part any other way than additive manufacturing.”

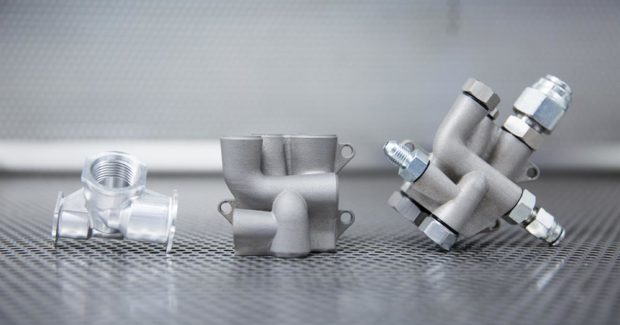

“The potential of additive manufacturing in terms of saving weight and improving efficiency is tremendous,” said Claughton. “For example, we took a long hard look at our hydraulics system. Before 3D printing came along, all of the parts in this system would have been manufactured by machining metal away from a solid block. The shapes that you can create with this method are limited, so the design is limited and so too is the efficiency. Hydraulic fluid doesn’t take kindly to going around hard corners, for instance, and there is a loss of power when it has to do so. With traditional techniques this might be the only way you can manufacture the part, but with additive manufacturing you can build it with smooth rounded corners that significantly improves efficiency in the fluid transfers involved. In addition to the improvements in efficiency, we can now build it much more lightly because we are only adding material specifically where it is needed. In the past, the geometry of manufacture on a lathe or other cutting tool meant that some material couldn’t be removed and we would have to carry around the excess weight. No longer.”

Renishaw has manufactured several parts for their hydraulics, and while the team is reluctant to reveal too much design detail, they have explained how the weight in a new AM manifold design was reduced by 60 percent, with an increase in performance efficiency of better than 20 percent. “Our involvement with Land Rover BAR is also helping to raise the bar in additive manufacturing,” commented David Ewing, a product marketing engineer in the Additive Manufacturing Products Division of Renishaw. “It’s a complex manufacturing option and there are considerations both in component design and process expertise. The best applications are the ones which use the minimum amount of material to achieve the design requirements, offer a functional benefit in service and have been designed with the manufacturing method in mind. Our work on hydraulic parts for the team is a perfect example.”

“They are at the top of this particular game and they have really helped us out with their facilities. This is one technology that’s here to stay, and its role within our build processes will only increase in the future,” stated Claughton.

Land Rover Ben Ainsile Racing Ltd., The Camber, East Street, Portsmouth, Hampshire PO1 2JJ, England, +44 (0) 23 9228 7814, land-rover-bar.americascup.com/en/.

Renishaw plc, New Mills, Wotton-under-Edge, Gloucestershire GL12 8JR, England, +44 1453 524524, Fax: +44 1453 524901, www.renishaw.com/additive.